Research on High-Precision Temperature Measurement Techniques for Integrated Circuits

-

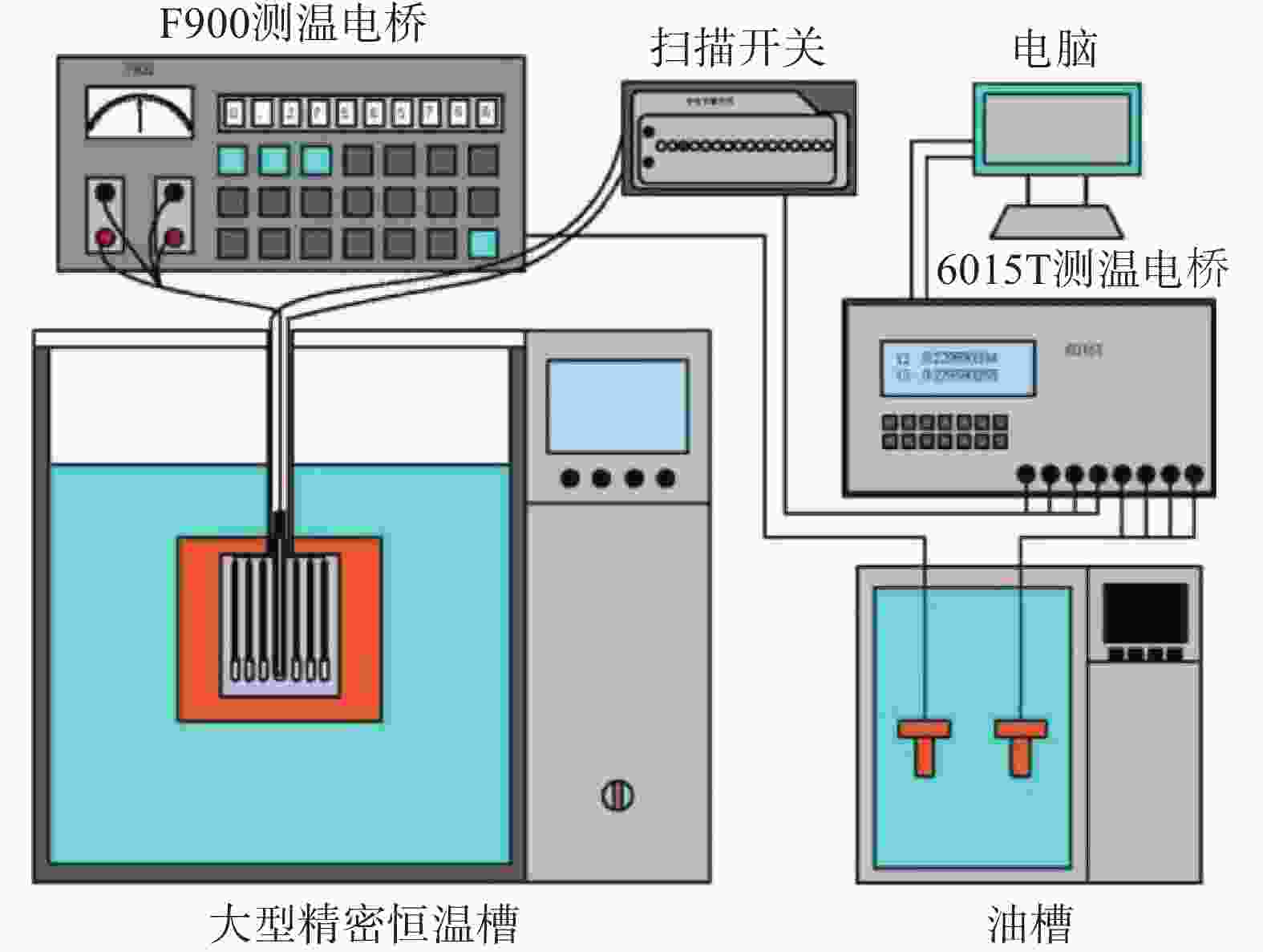

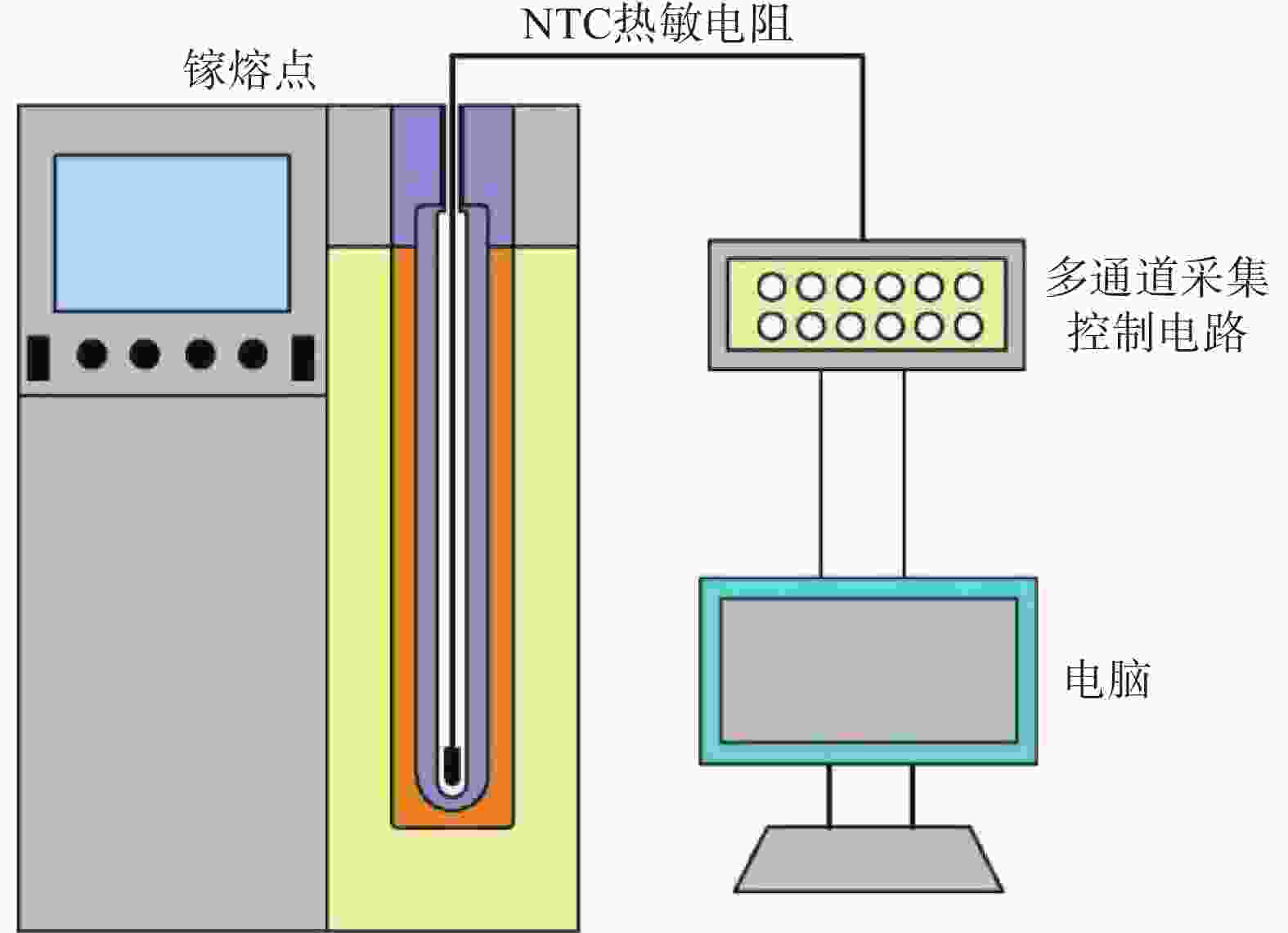

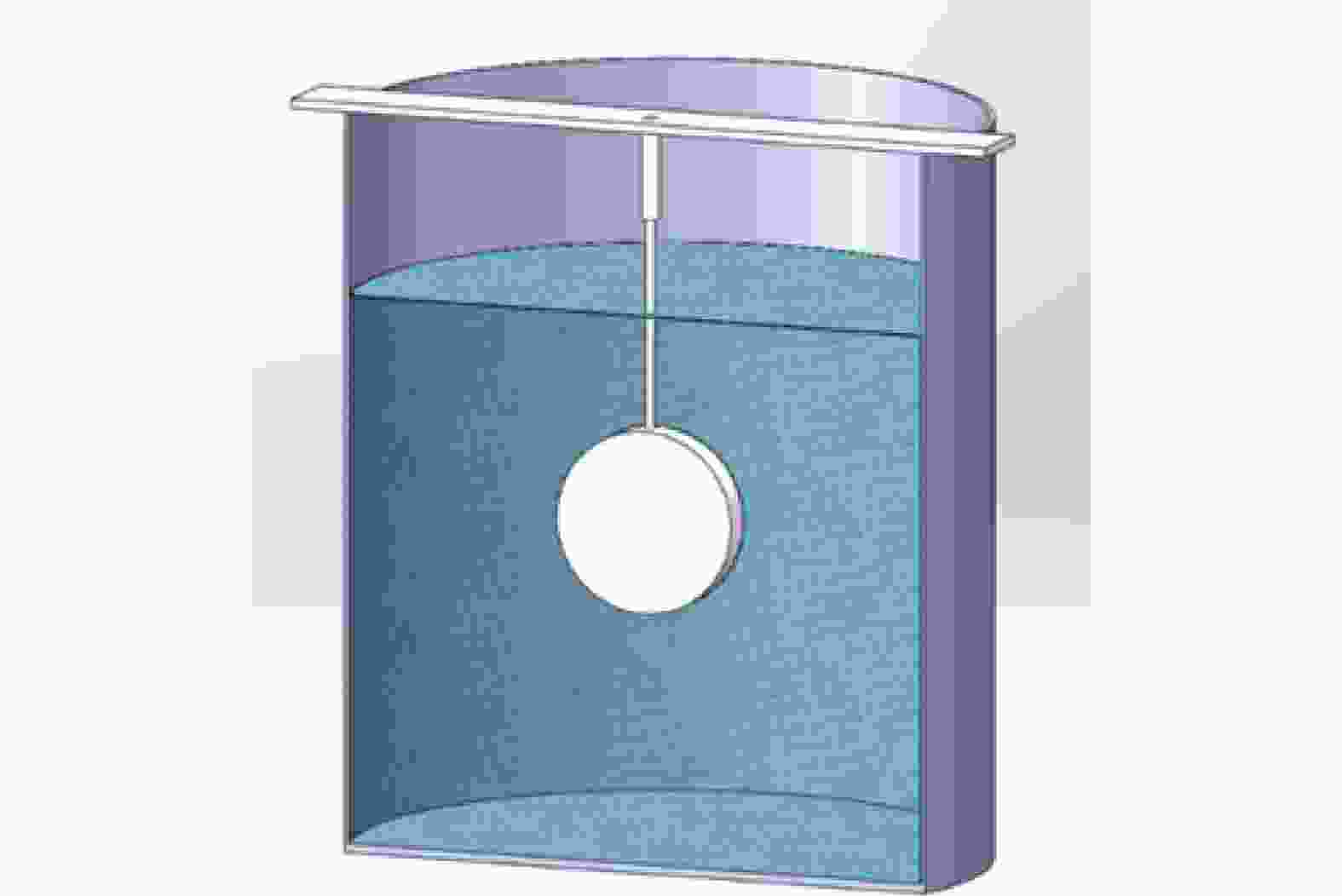

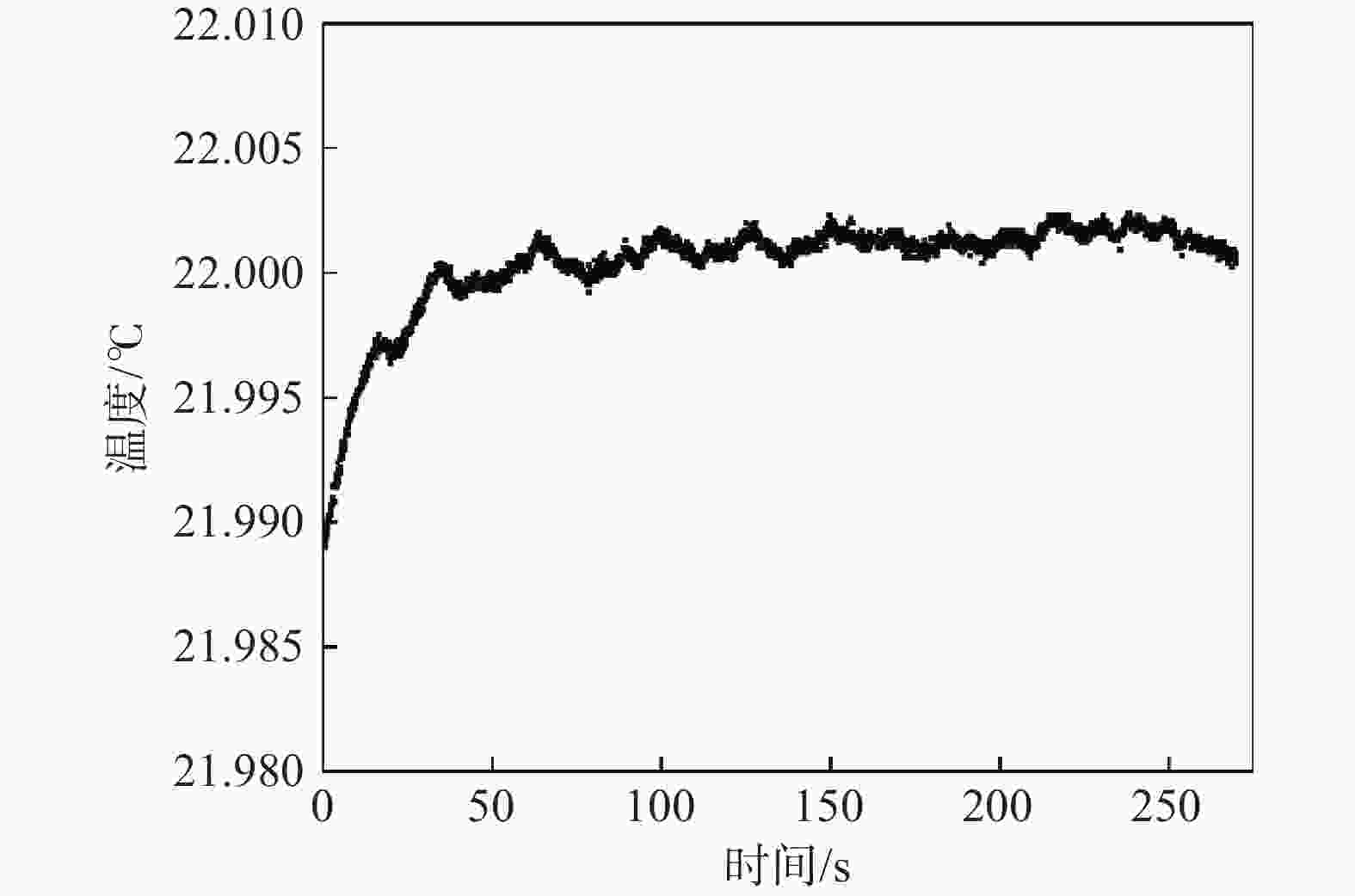

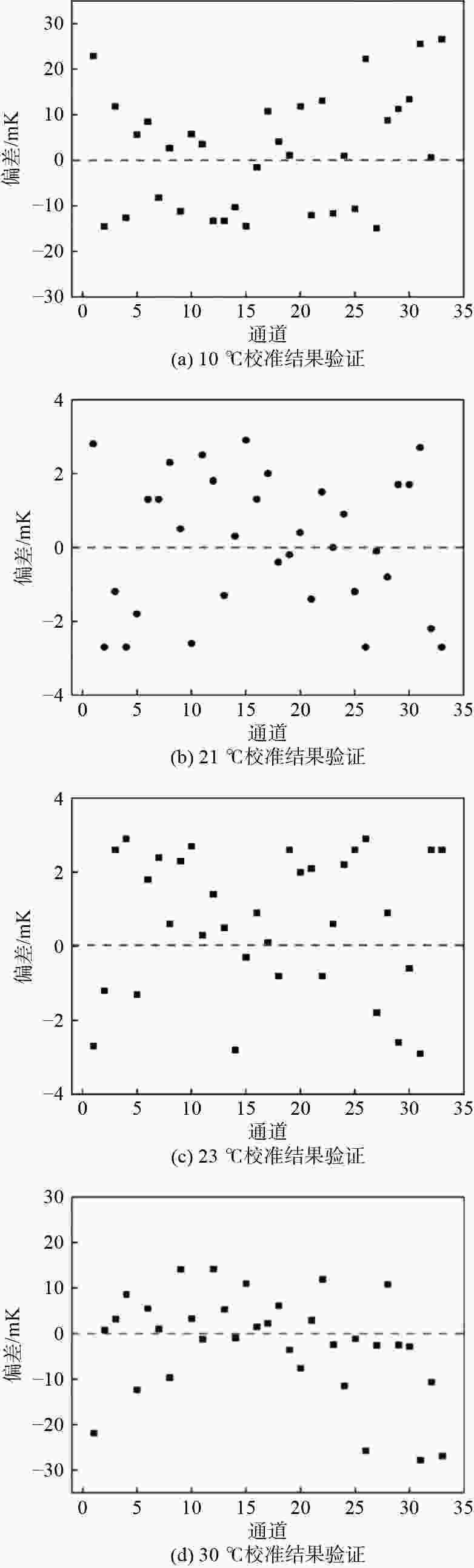

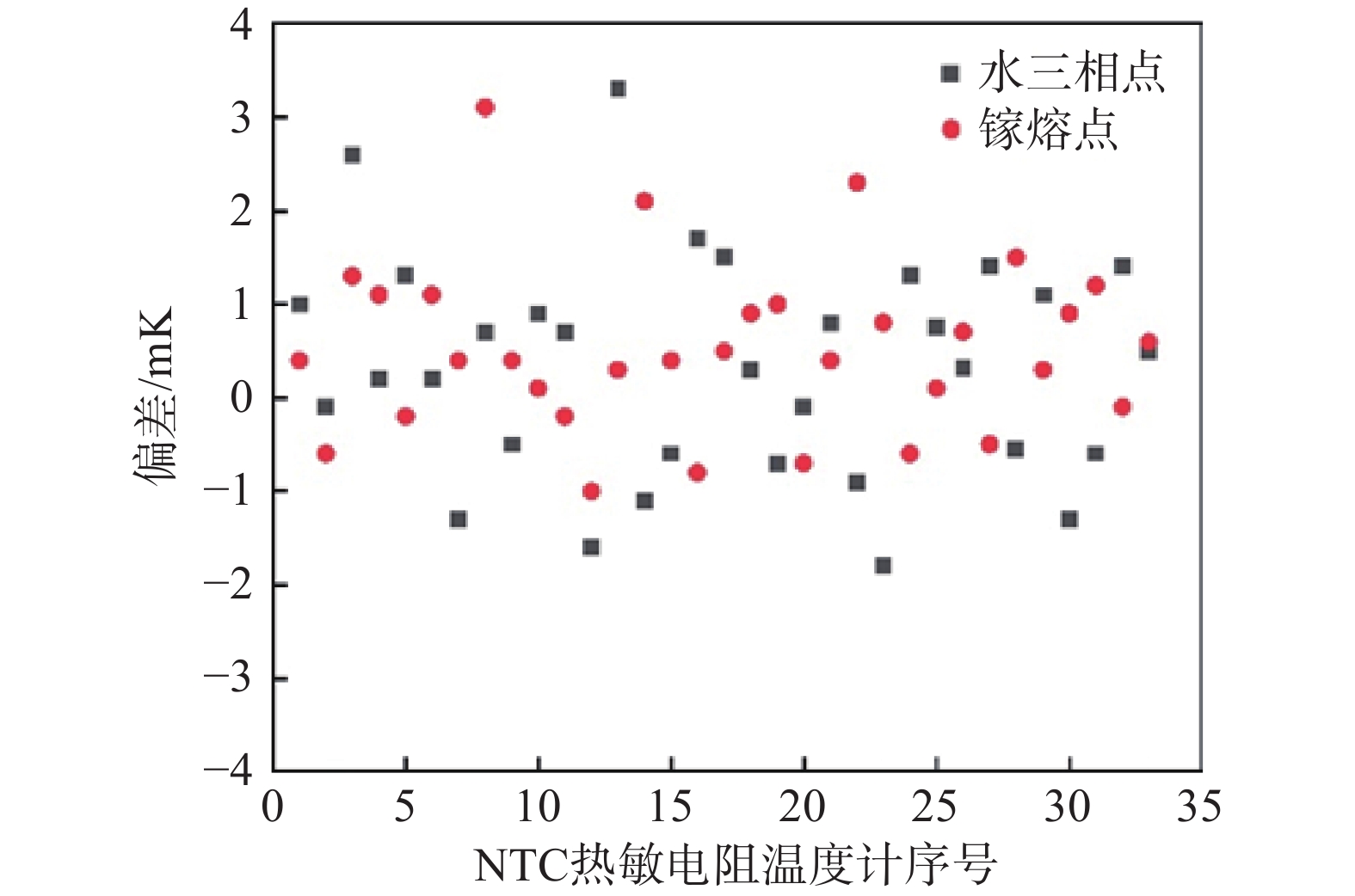

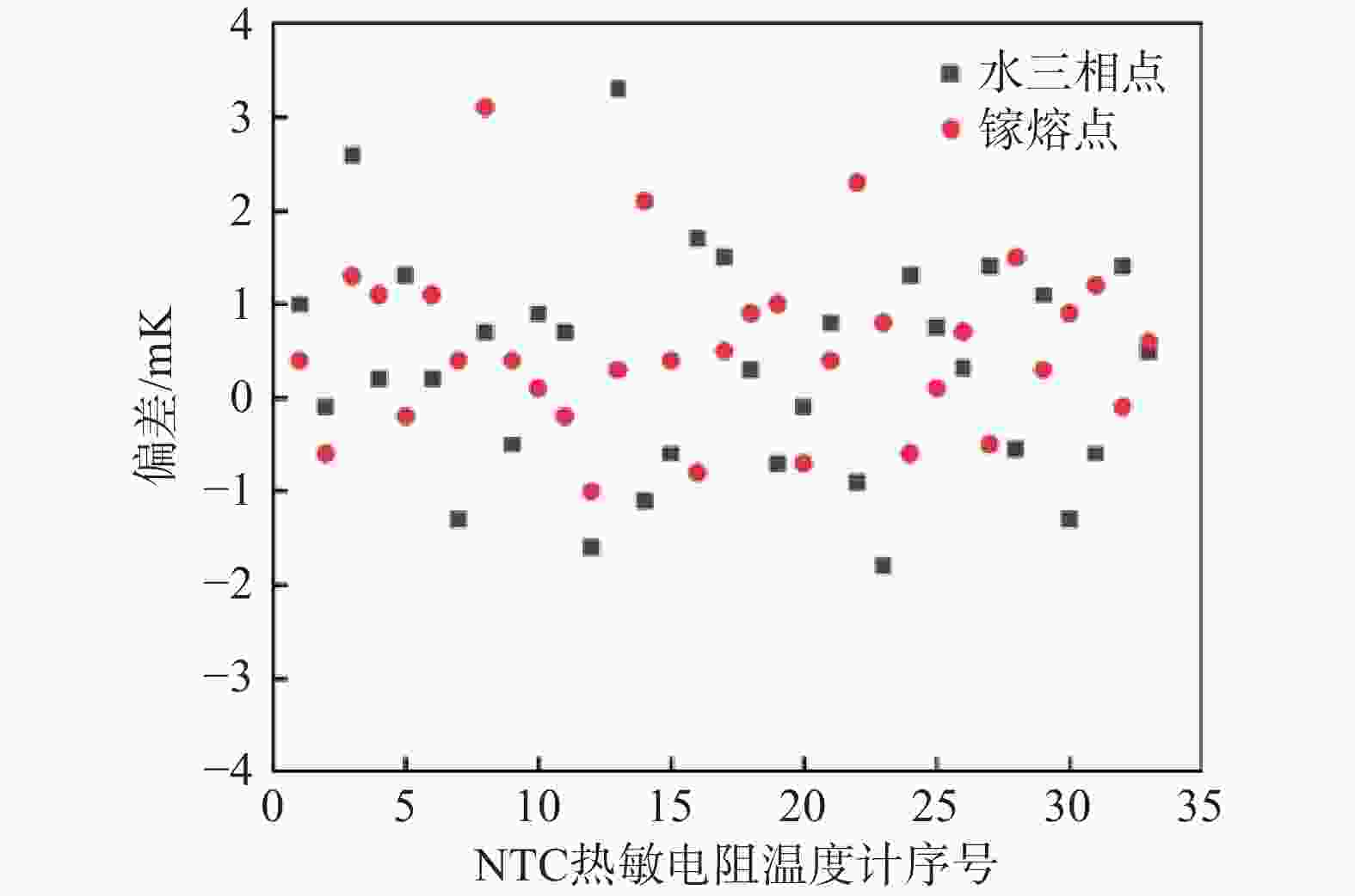

摘要: 集成电路从硅片制造、电路设计、晶圆加工、封装直到出厂存在近千道工艺,温度始终贯穿其中,温度的精密测量已成为不可或缺的关键技术。针对我国“缺芯少魂”的芯片产业发展困境及集成电路领域对于精密测温的迫切需求,展开传感器选型、长期稳定性考察及标定方法研究,发展多通道高精度测温电路技术,形成测温晶圆标定方法,研制了一套33路有线高精度晶圆温度测量系统。测试结果表明,NTC热敏电阻温度计能够满足高精度晶圆测温需求;拟合温度点的选取对于标定结果具有较大影响,通过不同标定温度点数量及分布的拟合结果比较,最终选取六点拟合,实现了21℃~23℃范围内偏差小于3 mK,测量不确定度7.4 mK(k=2)的结果。Abstract: The process of integrated circuit fabrication spans from silicon wafer manufacturing, circuit designing, wafer processing, packaging to the final product, involving nearly a thousand steps where precision temperature control plays a pivotal role. Given the pressing demand for precise temperature measurements in integrated circuit production and the current challenges faced by China's chip industry, this study investigated sensor selection, long-term stability, and calibration methods. Consequently, a multi-channel high-precision temperature measurement circuit technology was developed and a calibration method for temperature measurement wafers was established. Further, a 33-channel wired high-precision wafer temperature measurement system was constructed. Experimental results demonstrate that the NTC thermistor thermometer can satisfy the requirements of high-precision wafer temperature measurements. Calibration results greatly depend on the selection of fitting temperature points. Through comparison of different calibration temperature point distributions and quantities, a six-point fitting was chosen, achieving a deviation less than 3 mK within a 21℃~23℃ range, and measurement uncertainty of 7.4 mK (k=2).

-

Key words:

- metrology /

- integrated circuit /

- wafer /

- NTC thermistor /

- temperature measurement /

- uncertainty

-

表 1 晶圆测温系统测温不确定度

Table 1. Uncertainty of temperature measurement in wafer temperature measurement system

不确定度来源 标准不确定度 / mK(21℃~23℃) 多通道精密测温仪 1.4 NTC热敏电阻温度计稳定性 2.3 恒温槽稳定性、均匀性 1.7 多次测量重复性 1.7 SPRT校准 0.3 合成标准不确定度 3.6 扩展不确定度(k=2) 7.2 -

[1] MACK C A. Fifty years of Moore's law[J]. IEEE Transactions on semiconductor manufacturing, 2011, 24(2): 202-207. doi: 10.1109/TSM.2010.2096437 [2] WILLIAMSR S. What's next? [the end of Moore's law][J]. Computing in Science & Engineering, 2017, 19(2): 7-13. [3] 魏明, 张军. 一种便携式箱式电阻炉校准装置的研制[J]. 计量科学与技术, 2022, 66(12): 50-54. doi: 10.12338/j.issn.2096-9015.2022.0011 [4] HIKAVYY A, KRUV A, VAN OPSTAL T, et al. Investigation of C12 etch in view of extremely low temperature selective epitaxial processes[J]. Semiconductor Science and Technology, 2017, 32(11): 114006. doi: 10.1088/1361-6641/aa7e4b [5] RAHAMAN S Z, WANG I J, CHEN T Y, et al. Pulsewidth and temperature effect on the switching behavior of an etch-stop-on-MgO-barrier spin-orbit torque MRAM cell[J]. IEEE Electron Device Letters, 2018, 39(9): 1306-1309. doi: 10.1109/LED.2018.2856518 [6] SCHIAVONE G, MURRAY J, PERRY R, et al. Integration of electrodeposited Ni-Fe in MEMS with low-temperature deposition and Etch processes[J]. Materials, 2017, 10(3): 323. doi: 10.3390/ma10030323 [7] PEJOVIC M M, RISTIC G S, MILOSAVLJEVIC C S, et al. Influence of tube wall material type and tube temperature on the recombination processes of nitrogen ions and atoms in afterglow[J]. Journal of Physics D:Applied Physics, 2002, 35(20): 25. [8] YAMAMOTO H, KURODA H, ITO M, et al. Feature profiles on plasma etch of organic films by a temporal control of radical densities and real-time monitoring of substrate temperature[J]. Japanese Journal of Applied Physics, 2011, 51(1R): 16202. [9] HUANG P, YANG H. A design method to improve temperature uniformity on wafer for rapid thermal processing[J]. Electronics, 2018, 7(10): 213. doi: 10.3390/electronics7100213 [10] TSAI B K, BODYCOMB J, DEWITI D P, et al. Emissivity compensated pyrometry for specular silicon surfaces on the NIST RTP test bed [C]. New York: IEEE, 2004. [11] Kreider K G, DeWitt D P, Tsai B K, et al. Calibration Wafer for Temperature Measurements in RTP Tools [J]. Characterization and Metrology for ULSI Technology, 1998: 303-309. [12] Engelmann J, Chu D, Dupraz T, et al. Measuring the wafer temperature in CVD tools using the wireless SensArray High Temp-400 wafer [J]. IEEE ASMC, 2017: 161-164. [13] Mierden B, Tas M, Lof J, et al. ITRS roadmap is pushing wafer handling to milli-Kelvin performance [J]. International Conference of the European Society for Precision Engineering and Nanotechnology, 2017: 461-462. [14] Fang F, Vaid A, Vinslava A, et al. Correlation study of actual temperature profile and in-line metrology measurements for within-wafer uniformity improvement and wafer edge yield enhancement[J]. SPIE Metrology, Inspection, and Process Control for Microlithography XXXII, 2018, 10585: 1-6. [15] Kim J H, Koo Y, Song W, et al. On-Wafer Temperature Monitoring Sensor for Condition Monitoring of Repaired Electrostatic Chuck[J]. Electronics, 2022, 11(880): 1-10. [16] 范寒柏, 谢汉华. 基于NTC热敏电阻的三种高精度测温系统研究[J]. 传感技术学报, 2010, 23(11): 4. [17] 于丽丽, 王剑华, 殳伟群. NTC热敏电阻器在高精度温度测量中的应用[J]. 传感器技术, 2004(12): 75-77. [18] Cheng A, Zhang Y, Zhao Y, et al. Design of Temperature Measurement System for Electric Vehicles Air Conditioning[J]. International Core Journal of Engineering, 2020, 6(1): 236-242. [19] 李婷, 汪洪军, 孙建平, 等. 海洋用NTC热敏电阻温度计校准方法探索[J]. 计量科学与技术, 2021, 65(5): 55-61. doi: 10.12338/j.issn.2096-9015.2020.9027 [20] Joung W, Gam K. Pearce J V. Pressure dependence of the reference deep-ocean thermometers[J]. Metrological Applications, 2020, 27(1): e1870. [21] Guang Liu, Liang Guo, Chunlong Liu, et al. Evaluation of different calibration equations for NTC thermistor applied to high-precision temperature measurement[J]. Measurement, 2018, 120: 21-27. doi: 10.1016/j.measurement.2018.02.007 [22] White D R, Hill K, del Campo D, et al. Guide on secondary thermometry: Thermistor thermometry[R]. Bureau International des Poids et Mesures: Paris, France, 2014. [23] 梁亚星, 王秀峰, 金晓雪, 等. 氧化铝陶瓷材料电阻率精确测试方法[J]. 计量科学与技术, 2022, 66(1): 22-25. [24] 李超, 曾麟, 陈岳飞, 等. 恒温式量热仪校准精密温度计的可行性研究[J]. 计量科学与技术, 2022, 66(7): 38-44. [25] 王海涛, 文萌, 董亮, 等. 恒温槽温度梯度实验研究[J]. 计量科学与技术, 2021, 65(10): 50-53,5. -

作者投稿

作者投稿 专家审稿

专家审稿 编辑办公

编辑办公

下载:

下载: