| [1] |

张国雄. 三坐标测量机[M]. 天津: 天津大学出版社, 1999.

|

| [2] |

WECKENMANN A, JIANG X, SOMMER K, et al. Multisensor data fusion in dimensional metrology[J]. CIRP Annals - Manufacturing Technology, 2009, 58: 701-721. doi: 10.1016/j.cirp.2009.09.008

|

| [3] |

NEUSCHAEFER-RUBE U, EHRIG W, NEUGEBAUER M, et al. Test procedures and artefacts for optical coordinate metrology[J]. SPIE, 2009, 7133: 713304.

|

| [4] |

朱嘉. 基于视觉与触觉集成传感的多坐标组合测量系统的研究[D]. 天津: 天津大学, 2010.

|

| [5] |

J P Kruth, M Bartscher, S Carmignato, et al. Computed tomography for dimensional metrology[J]. CIRP Annals, 2011, 60(2): 821-842.

|

| [6] |

杨泽南, 黄子婴, 查海勇, 等. 基于森林球的工业CT测量不确定度评定与分析[J]. 光学精密工程, 2023, 31(11): 1672-1683. doi: 10.37188/OPE.20233111.1672

|

| [7] |

ISO. Geometrical product specifications(GPS)-Acceptance and reverification tests for coordinate measuring systems(CMS)-Part 9: CMMs with multiple probing systems : ISO 10360-9[S]. Geneva: International Organization for Standardization, 2014

|

| [8] |

ISO. Geometrical product specifications (GPS) - Acceptance and reverification tests for coordinate measuring machines (CMM) - Part 5: CMMs using single and multiple stylus contacting probing systems : ISO 10360-5 [S]. Geneva: International Organization for Standardization, 2010.

|

| [9] |

ISO. Geometrical product specifications (GPS) - Acceptance and reverification tests for coordinate measuring machines (CMM) - Part 7: CMMs equipped with imaging probing systems : ISO 10360-7 [S]. Geneva: International Organization for Standardization, 2011.

|

| [10] |

ISO. Geometrical product specifications (GPS). Acceptance and reverification tests for coordinate measuring systems (CMS). Part 8: CMMs with optical distance sensors : ISO 10360-8 [S]. Geneva: International Organization for Standardization, 2013.

|

| [11] |

Wei H , Wang W , Pei L , et al. Concentricity calibration of photogrammetry retro-reflector target[C]. International Society for Optics and Photonics, 2016.

|

| [12] |

HAMMAD M S , AL-AHMARI A. New developments in coordinate measuring machines for manufacturing industries[J]. Int. J. Metrol. Qual. Eng, 2014, 5 : 101-111.

|

| [13] |

GLEN A TURLEY. Evaluation of a multi-sensor horizontal dual arm Coordinate Measuring Machine for automotive dimensional inspection[J]. Int J Adv Manuf Technol, 2014, 72: 1665-1675. doi: 10.1007/s00170-014-5737-3

|

| [14] |

JANICE R G, WILLIAM A C. Evaluating a hybrid 3-dimensional metrology system: merging data from optical and touch probe devices[J]. Proc. of SPIE, 2011, 8133: 813301. doi: 10.1117/12.915357

|

| [15] |

CARMIGNATO S, VOLTAN A, SAVIO E. Metrological performance of optical coordinate measuring machines under industrial conditions[J]. CIRP Annals - Manufacturing Technology, 2010, 59: 497-500. doi: 10.1016/j.cirp.2010.03.128

|

| [16] |

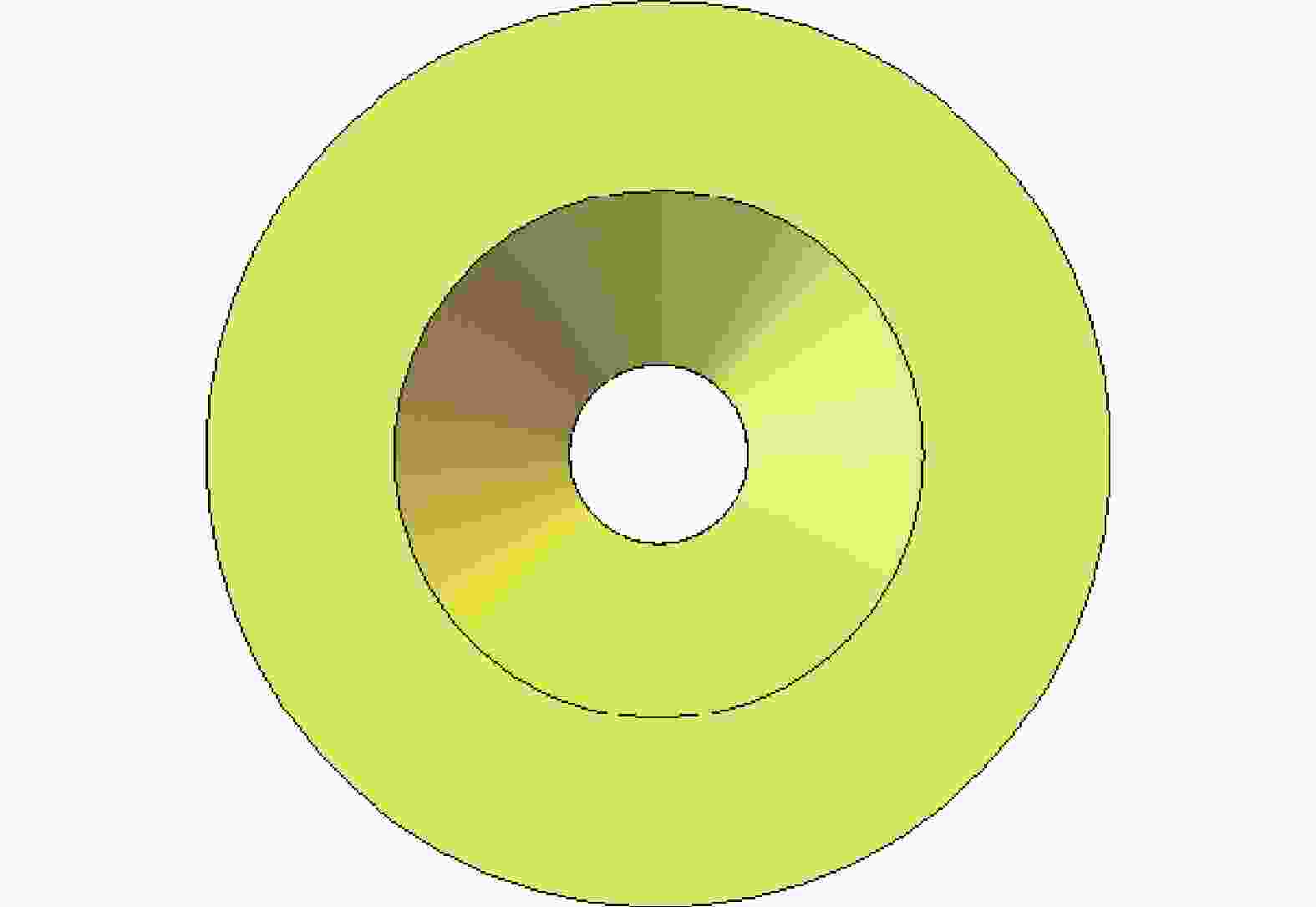

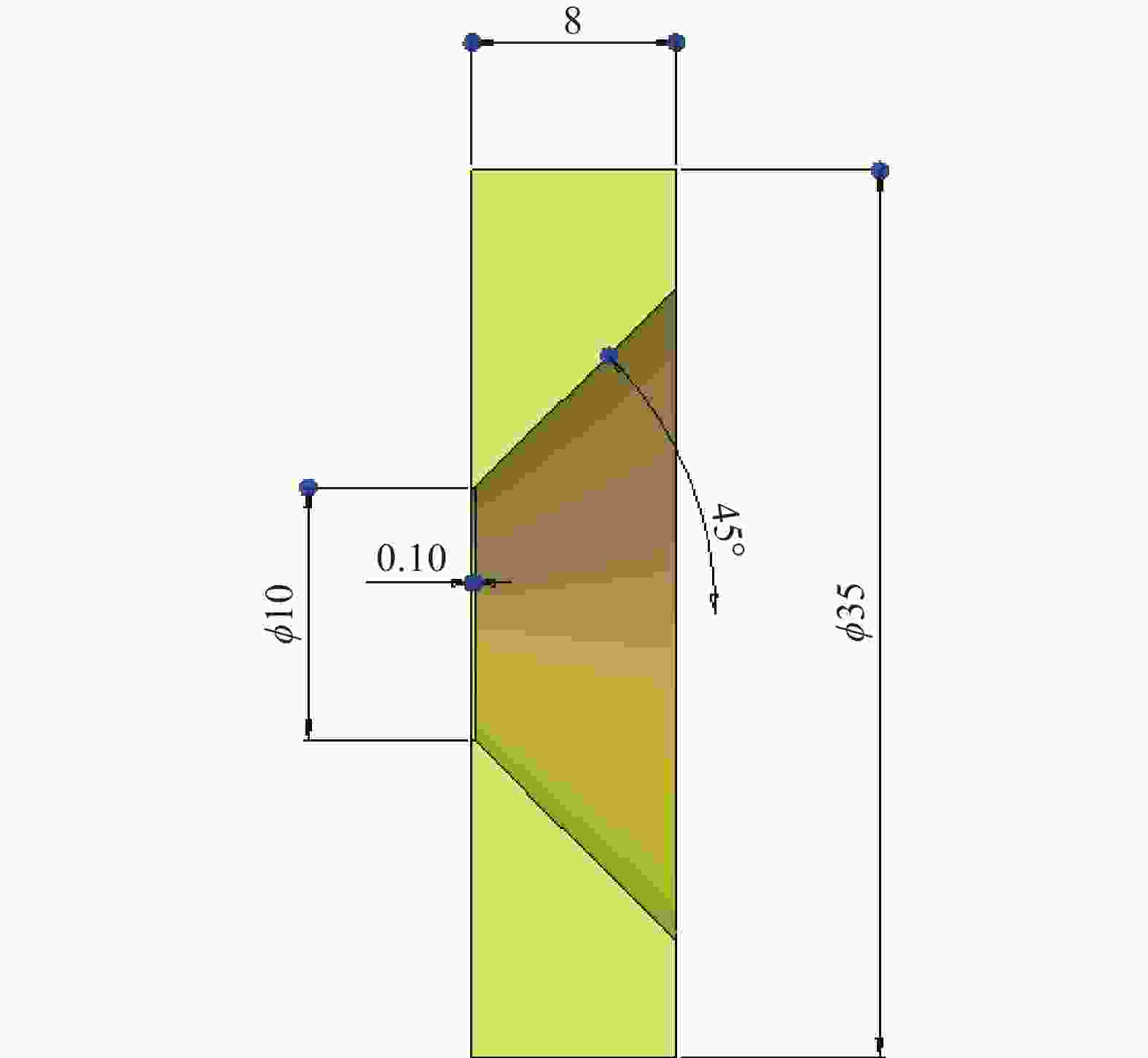

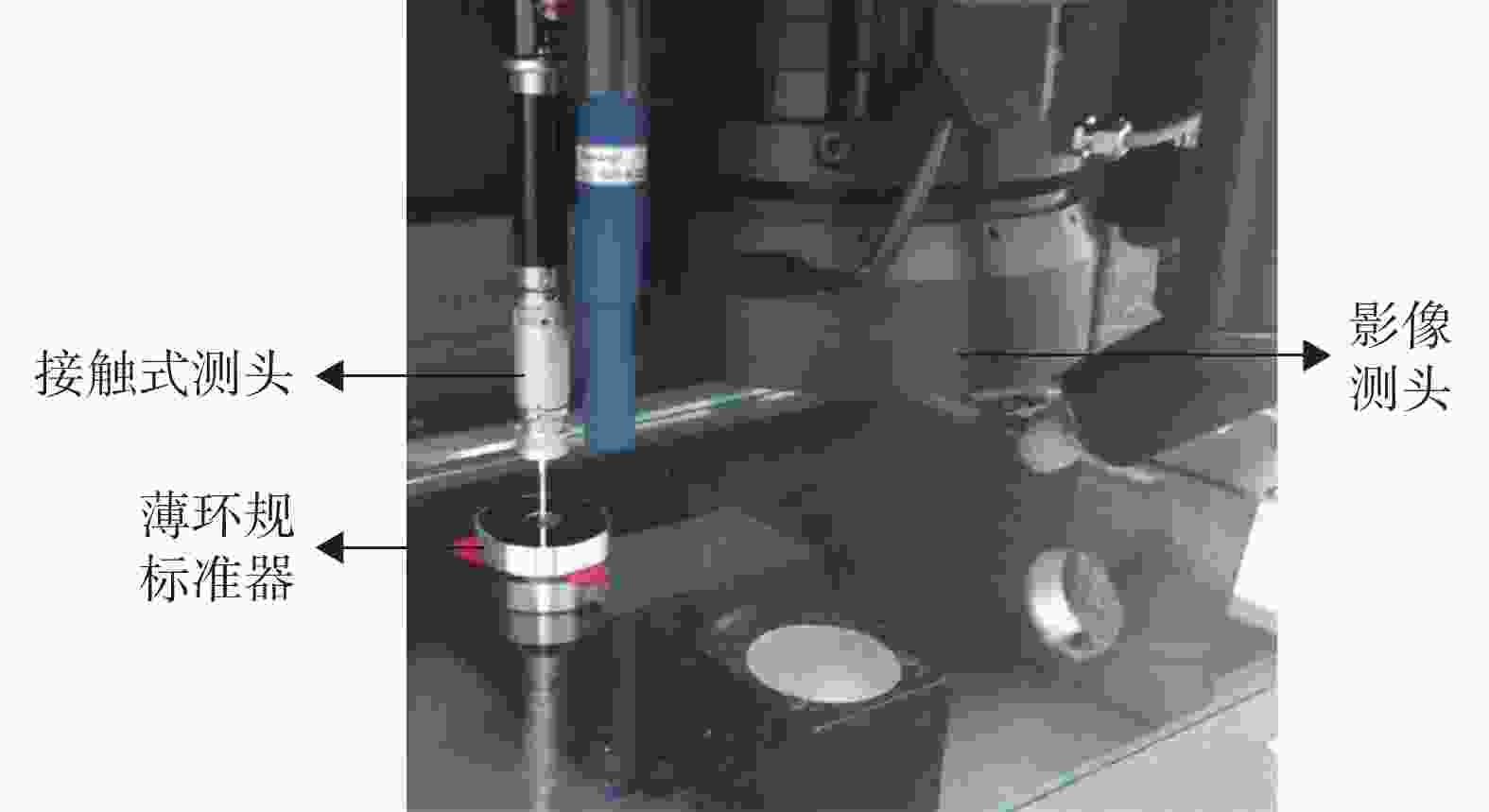

位恒政, 王为农, 裴丽梅, 等. 用于多传感器坐标测量机探测误差评价的薄环规标准器[J]. 光学精密工程, 2016, 24(3): 521-525.

|

| [17] |

马小军, 高党忠, 杨蒙生, 等. 应用白光共焦光谱测量金属薄膜厚度[J]. 光学精密工程, 2011, 19(1): 17-22.

|

| [18] |

Peter Andersson, Björn Hemming. Determination of wear volumes by chromatic confocal measurements during twin-disc tests with cast iron and steel[J]. Wear, 2015, 338: 95-104.

|

| [19] |

V Rishikesan, G L Samuel. Evaluation of surface profile parameters of a machined surface using confocal displacement sensor[J]. Procedia Materials Science, 2014(5): 1385-1391.

|

| [20] |

柳晓飞, 邓文怡, 牛春晖, 等. 一种新型光谱共焦位移测量系统研究[J]. 传感器与微系统, 2013, 32(4): 34-36.

|

| [21] |

ISO. Geometrical product specification (GPS) – Surface texture: Areal –Part 602: Nominal characteristics of non-contact (chromatic confocal probe) instruments. International Organization for Standardization: ISO 25178-602 [S] . Geneva: International Organization for Standardization, 2010.

|

| [22] |

H Nouira, N El-Hayek, X Yuan, et al. Characterization of the main error sources of chromatic confocal probes for dimensional measurement[J]. Measurement Science and Technology, 2014(25): 044011.

|

| [23] |

H Nouira, J-A Salgado, N El-Hayek, et al. Setup of a high-precision profilometer and comparison of tactile and optical measurements of standards[J]. Measurement Science and Technology, 2014(25): 044016.

|

| [24] |

王为农. 校准: 定义的解读和结果的测量不确定度表达[J]. 计量科学与技术, 2023, 67(2): 58-61.

|

| [25] |

位恒政, 王为农, 任国营, 等. 光谱共焦传感器探测误差的研究[J]. 计量学报, 2017, 38(6A): 1-4.

|

| [26] |

于宝峰. 金属材料力学性能测试方法发展[J]. 冶金与材料, 2022(4): 150-151.

|

| [27] |

李庆. 金属材料硬度的研究[J]. 自动化应用, 2023, 64(z1): 25-28.

|

| [28] |

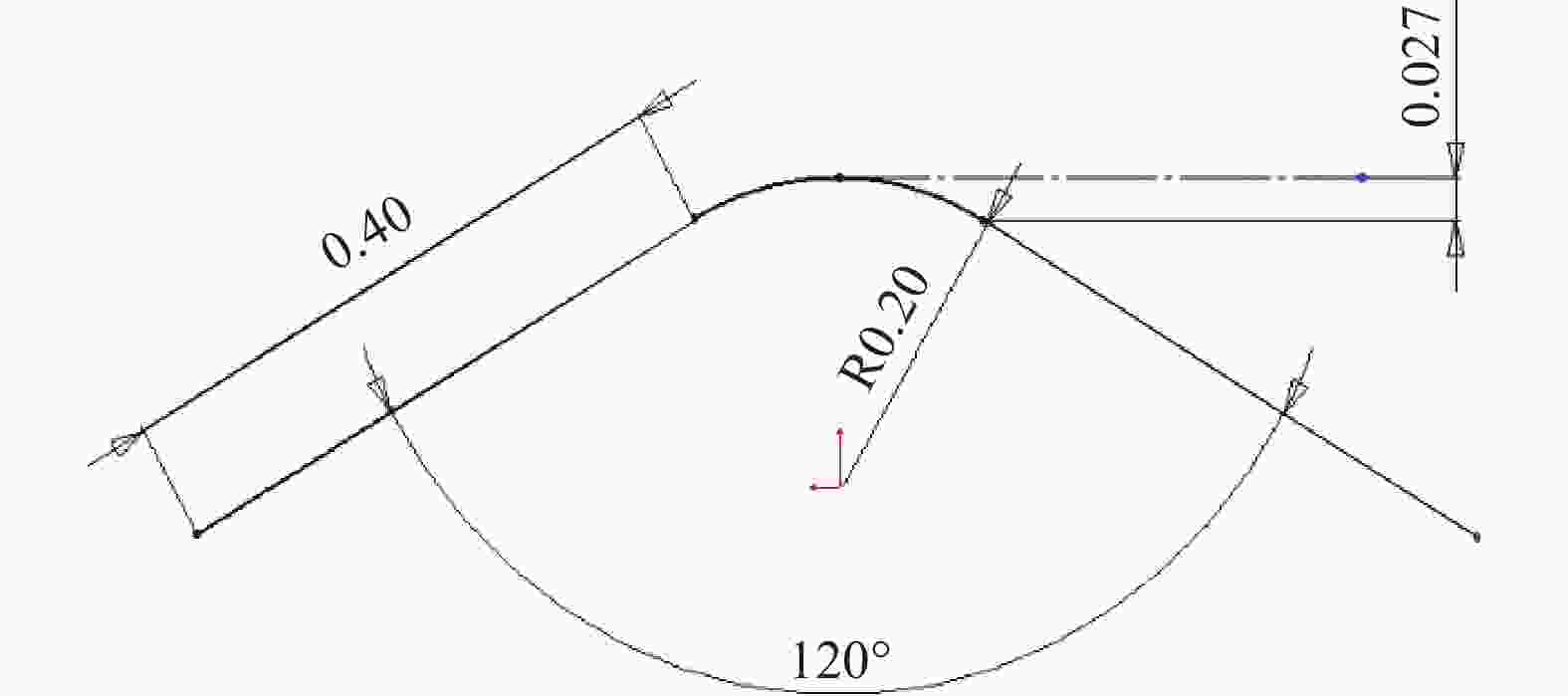

赵国夫. 洛氏硬度计压头对示值的影响[J]. 计量与测试技术, 2009, 36(4): 26-27.

|

| [29] |

李杨, 张凯林, 石伟. 激光扫描共聚焦显微镜在微小硬度压痕测量中的应用研究[J]. 计测技术, 2019, 39(6): 46-49.

|

| [30] |

位恒政, 王为农, 裴丽梅, 等. 面向任务的坐标测量机测量不确定度评价方法[J]. 计量科学与技术, 2021, 65(5): 115-119,54.

|

作者投稿

作者投稿 专家审稿

专家审稿 编辑办公

编辑办公

下载:

下载: