Research Progress on Error Factors and Technology of Ultrasonic Flow Meter

-

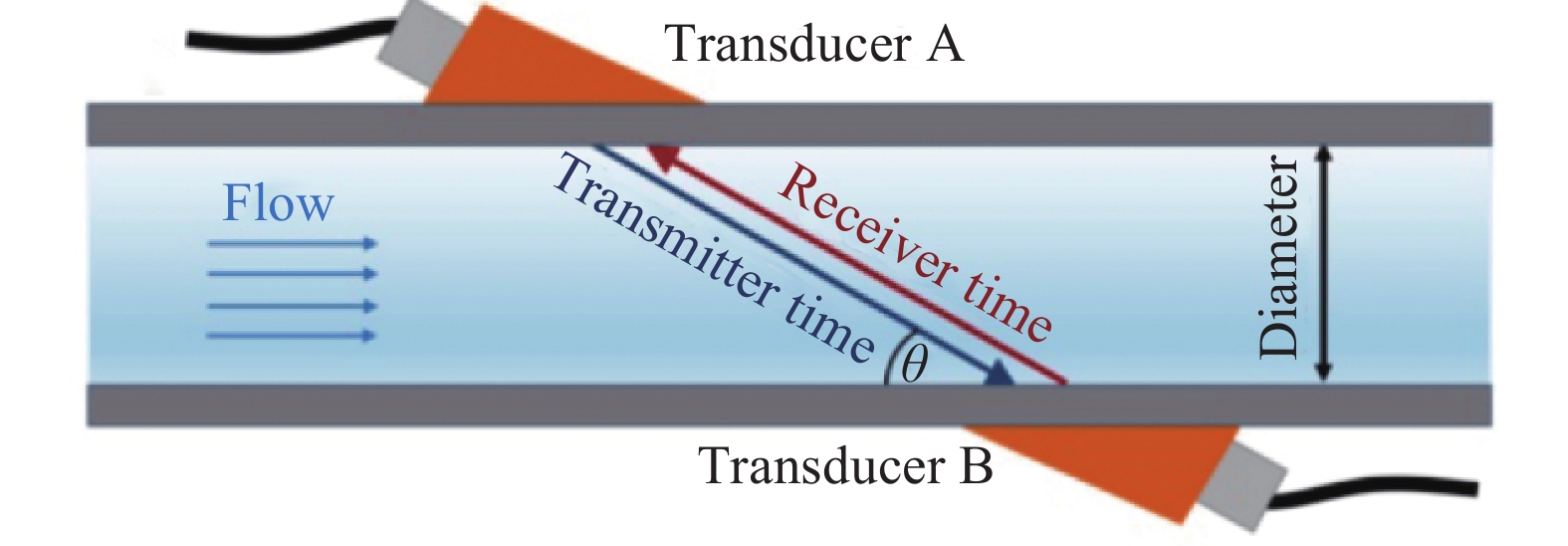

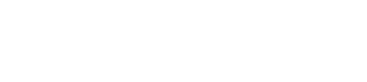

摘要: 超声波流量计在测量流量上表现出高精度和瞬时测量的优势,具有显著的应用潜力,对于油气安全存储、低损耗运输和公平结算有着重要意义。针对时差法、频率法、互相关法和多普勒法4种流量计算原理方法,分析了高精度超声波流量计工作机理,并从湍流特质、仪表结构和环境因素3个角度揭示流速和温度对流量测量精度的影响,探讨了仪表几何形状变化对流速场干扰,综述了超声波流量计误差因素和减小误差技术办法,为高精度流量计技术创新提供思路指导。Abstract: [Abstract]Ultrasonic flow meters show the advantages of high precision and instantaneous measurement in flow measurement, and have significant application potential, which is of great significance for safe oil and gas storage, low loss transportation and fair settlement. This paper analyzes the working mechanism of high-precision ultrasonic flow meter based on four flow calculation principles, namely, time difference method, frequency method, cross-correlation method and Doppler method, and reveals the influence of flow velocity and temperature on flow measurement accuracy from three perspectives of turbulence characteristics, instrument structure and environmental factors, and discusses the interference of meter geometry change on flow velocity field. This paper summarizes the error factors of ultrasonic flow meter and the technical methods to reduce the error, and provides ideas and guidance for the innovation of high-precision flow meter technology through research and prospect.

-

Key words:

- metrology /

- ultrasonic wave /

- flow meter /

- errors

-

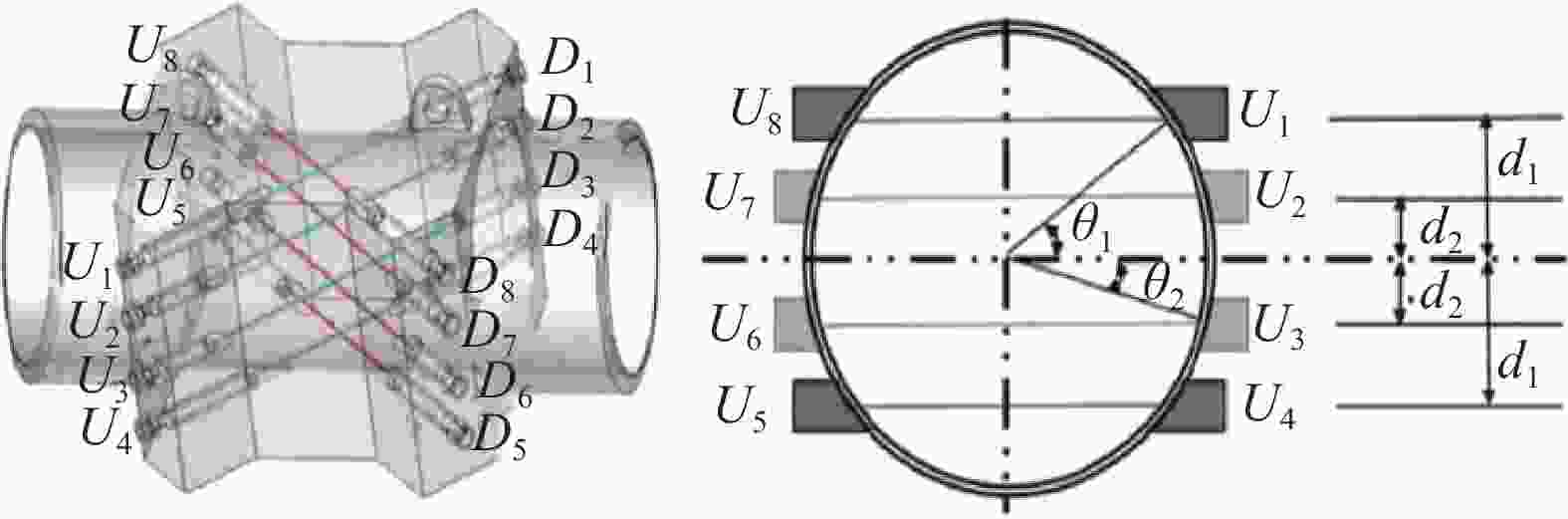

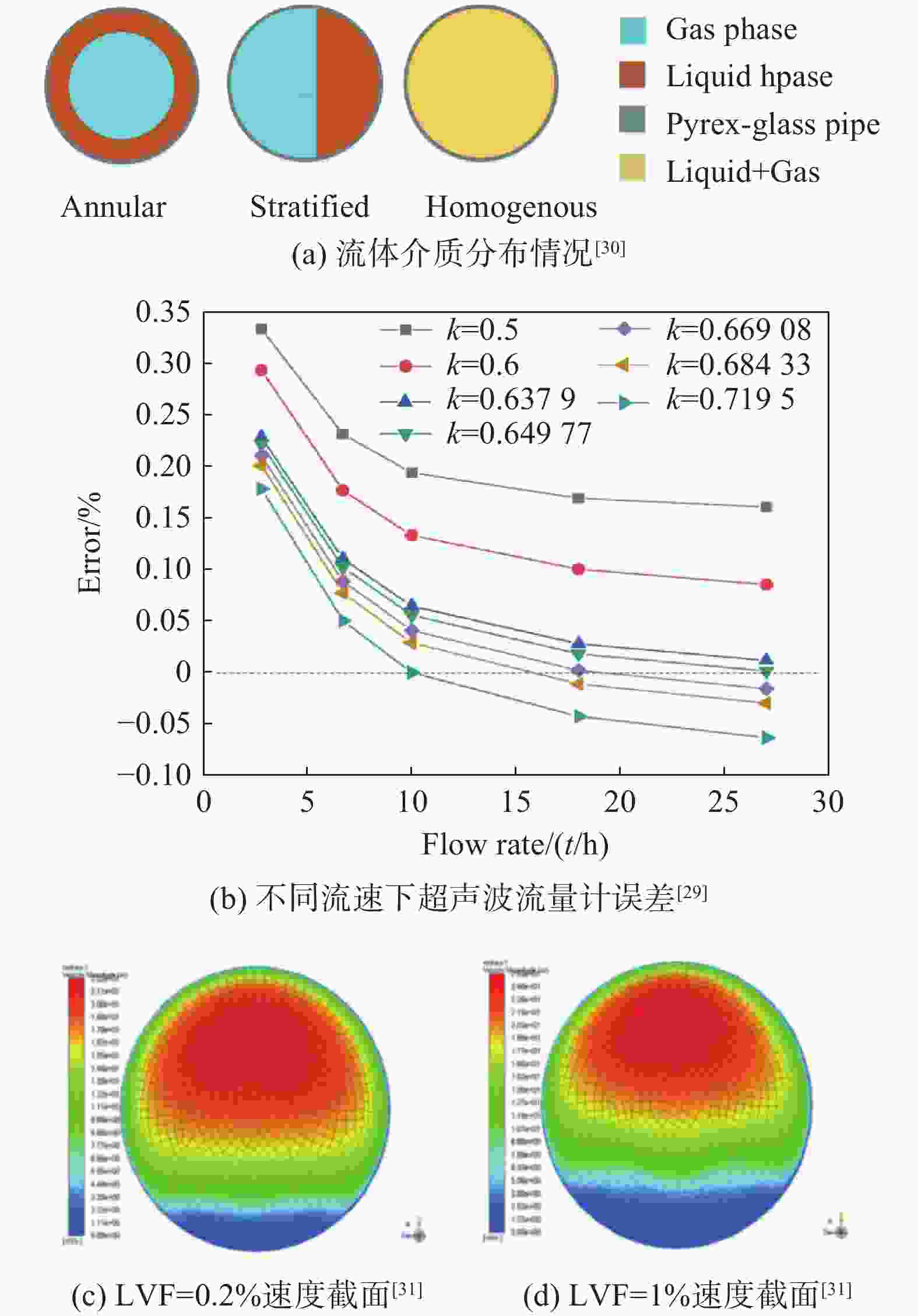

图 2 多声道布置结构外视图[14]

Figure 2. Exterior view of multi-channel structure

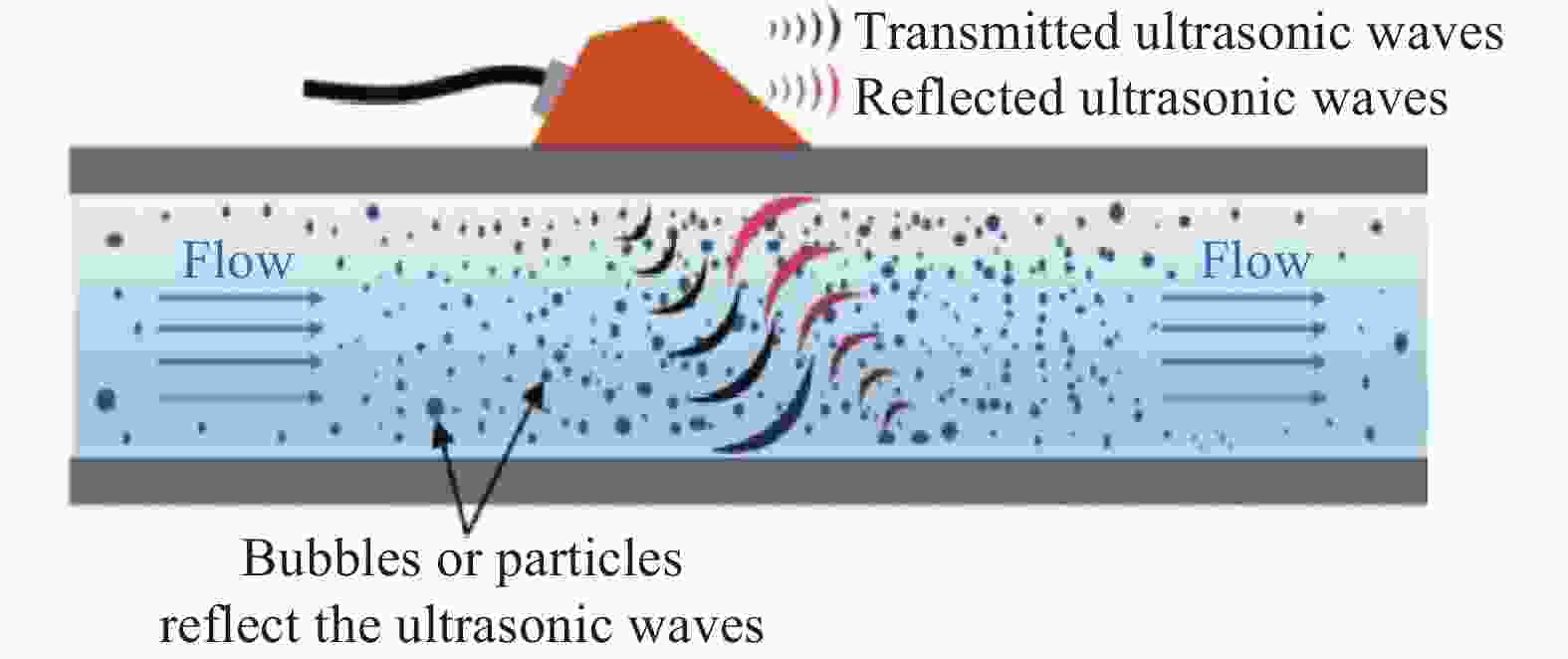

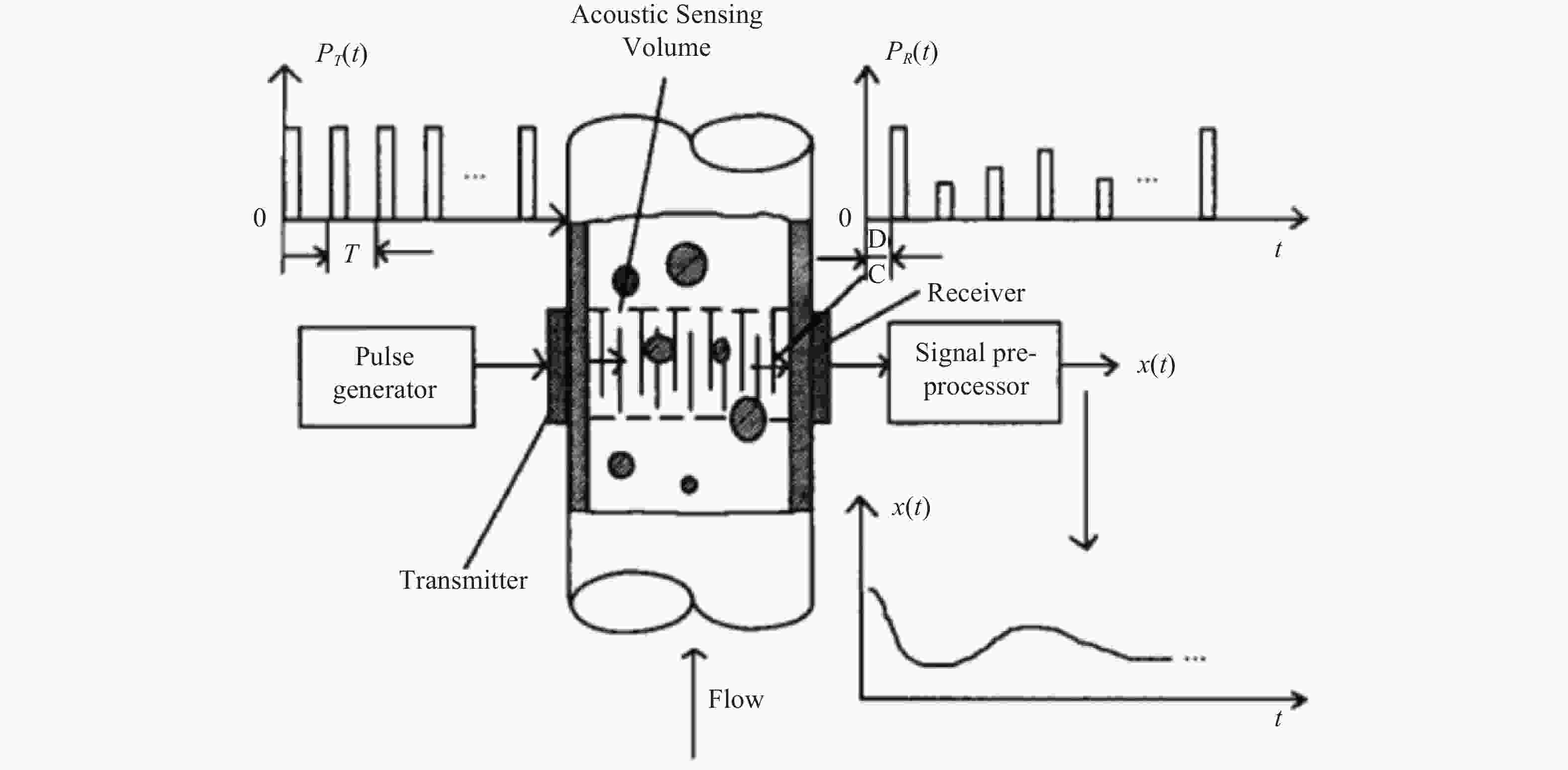

图 6 超声脉冲的产生[26]

Figure 6. Generation of ultrasound pulses

-

[1] 万大川, 冯倩倩, 高进胜, 等. 流量计量在“碳达峰、碳中和”的重要意义和前景展望[J]. 工业计量, 2022, 32(S1): 34-37. [2] 张淞. 超声波流量计在气体计量中的应用策略[J]. 石化技术, 2023, 30(11): 20-22. [3] 李国林, 张泽成, 张雪娜, 等. 泥浆管道的多普勒超声流量计实验[J]. 实验室研究与探索, 2022, 41(9): 26-30,195. [4] 赵楠楠, 徐安察, 胡亮, 等. 基于声速追踪的超声波液体流量计量方法[J]. 仪表技术与传感器, 2022(9): 41-46. [5] JI B, Park J H, Cho S H. Feasibility study on clamp-on ultrasonic flowmeter based on EMAT[J]. Journal of the Korean Society for Nondestructive Testing, 2018, 38(5): 316-321. doi: 10.7779/JKSNT.2018.38.5.316 [6] Ren R, Wang H L, Sun X L, et al. Design and implementation of an ultrasonic flowmeter based on the cross-correlation method[J]. Sensors, 2022, 22(19): 7470. doi: 10.3390/s22197470 [7] Kumar J S, Kamaraj A, Sundaram C K, et al. A comprehensive review on accuracy in ultrasonic flow measurement using reconfigurable systems and deep learning approaches[J]. AIP Advances, 2020, 10(10): 105221. doi: 10.1063/5.0022154 [8] Sun B, Chen S Z, Liu Q, et al. Review of sewage flow measuring instruments[J]. Ain Shams Engineering Journal, 2021, 12(2): 2089-2098. doi: 10.1016/j.asej.2020.08.031 [9] 李雪菁, 姚新红, 张进明. 高温液态金属流量在线测量方法与技术综述[J]. 仪器仪表学报, 2022, 43(1): 62-72. [10] 宿彬, 张鹏飞, 程东旭, 等. 超声波流量计温度补偿算法研究综述[J]. 现代电子技术, 2023, 46(13): 115-120. [11] Li M N, Li Z L, Li C H. In-use measurement of ultrasonic flowmeter based on machine learning[J]. Measurement, 2023, 223: 113721. doi: 10.1016/j.measurement.2023.113721 [12] Nour A M, Hussain M M. A Review of the real-time monitoring of fluid-properties in tubular architectures for industrial applications[J]. Sensors, 2020, 20(14): 3907. doi: 10.3390/s20143907 [13] 渠鹏程. 广角时差法超声波明渠流量计的设计[D]. 青岛: 山东科技大学, 2020. [14] 刘岩, 魏华彤, 白天, 等. 高精度主给水超声波流量计的不确定度分析方法[J]. 江苏水利宇航计测技术, 2023, 43(4): 1-7. [15] 梁柱志. 南水北调中线配套工程中超声波流量计的应用研究[J]. 河北水利, 2022(8): 46-47. [16] 邓山, 赵昕, 张莉, 等. 南水北调工程陶岔站时差法流量计推流技术研究[J]. 人民长江, 2022, 53(4): 86-90. [17] 陈武, 黄毅, 力刚, 等. 时差法超声波测流系统在刘老涧泵站的应用分析[J]. 江苏水利, 2022(z2): 61-64. [18] 陈亦文, 邱公伟. 超声波流量计的原理、应用和发展[J]. 福建电脑, 2002(9): 34-36. [19] Nguyen T H L, Park S. Multi-angle liquid flow measurement using ultrasonic linear array transducer[J]. Sensors, 2020, 20(2): 388. doi: 10.3390/s20020388 [20] Yoshida T, Furuichi N. Development of controllable volumetric prover for evaluating responsiveness of flowmeter under controlled-transient flows[J]. Measurement, 2023, 208: 112456. doi: 10.1016/j.measurement.2023.112456 [21] Park J, Kim J, Chang Y, et al. Analysis of the time-velocity curve in phase-contrast magnetic resonance imaging: a phantom study[J]. Computer Assisted Surgery, 2019, 24: 3-12. doi: 10.1080/24699322.2019.1649066 [22] Zhang H R, Dong F, Tan C. Liquid-solid two-phase flow rate measurement by electrical and ultrasound Doppler sensors[J]. IEEE Transactions on Instrumentation and Measurement, 2022, 71: 7504609. [23] 陈芙蓉, 裴锐. 多普勒超声流量计的研究与应用[J]. 仪器仪表用户, 2023, 30(11): 1-3,29. [24] 聂仁智, 崔永俊. 基于时差法的超声波液体流量测量系统设计[D]. 太原: 中北大学, 2023. [25] 胡玉婷. 基于拟合互相关法的气体超声波流量计计量算法研究[D]. 郑州: 郑州大学, 2021. [26] Xu L A, Yang H L, Zhang T, et al. A clamp-on ultrasound cross-correlation flowmeter for liquid/solid two-phase flow measurement[J]. Flow Measurement and Instrumentation, 1994, 5(3): 203-208. doi: 10.1016/0955-5986(94)90021-3 [27] 柏思忠. 一种 λ型互相关时差法超声波流量检测方法[J]. 自动化仪表, 2016, 37(2): 82-85. [28] 任大呈, 魏华彤, 刘岩, 等. 探头扰流对多声道超声波流量计测量结果影响研究[J]. 仪表技术与传感器, 2023(2): 110-114. [29] Guo S N, Xiang N L, Li B A, et al. Integration method of multipath ultrasonic flowmeter based on velocity distribution[J]. Measurement, 2023, 207: 112388. doi: 10.1016/j.measurement.2022.112388 [30] Basahel A, Sattari M A, Taylan O, et al. Application of feature extraction and artificial intelligence eechniques for increasing the accuracy of X-ray radiation based two phase flow meter[J]. Mathematics, 2021, 9(11): 1227. doi: 10.3390/math9111227 [31] Zheng D D, Zhai M X. Study on the channel weight of ultrasonic flowmeter in wet gas measurement[C]. 2022 IEEE Instrumentation and Measurement Technology Conference, Ottawa, Canada, 2022: 9806643. [32] Kang L, Feeney A, Su R L, et al. Flow velocity measurement using a spatial averaging method with two-dimensional flexural ultrasonic array technology[J]. Sensors, 2019, 19(21): 4786. doi: 10.3390/s19214786 [33] 白天, 魏华彤, 刘岩, 等. 高温高压对超声流量计表体变形量及测量精度的影响[J]. 自动化与仪表, 2023, 38(4): 112-116,120. [34] 邱学孟. 民用超声水表的设计与实现[D]. 成都: 电子科技大学, 2022. [35] Ge L, Deng H X, Wang Q, et al. Study of the influence of temperature on the measurement accuracy of transit-time ultrasonic flowmeters[J]. Sensor Review, 2019, 39(2): 269-276. doi: 10.1108/SR-01-2018-0005 [36] Sahu S, Bhope K, Prajapati A, et al. Sonic velocity measurement in molten Pb-Li (16) at high temperature for ultrasonic flowmeter applications[J]. Flow Measurement and Instrumentation, 2022, 88: 102271. doi: 10.1016/j.flowmeasinst.2022.102271 [37] 杨宗良, 宿彬, 张勍, 等. 流场因素对超声波气体流量计测量精度影响[J]. 现代电子技术, 2023, 46(15): 89-94. [38] Sakhavi N, Nouri N M. Generalized velocity profile evaluation of multipath ultrasonic phased array flowmeter[J]. Measurement, 2022, 187: 110302. doi: 10.1016/j.measurement.2021.110302 [39] Chen W L, Wu J J, Li C H. The Investigation on the flow distortion effect of header to guarantee the measurement accuracy of the ultrasonic gas flowmeter[J]. Applied Sciences, 2021, 11(8): 3656. doi: 10.3390/app11083656 [40] Alaeddin M A, Hashemabadi S H, Mousavi S F. Numerical study on the effect of circumferential position of utrasonic transducers on ultrasonic cross-correlation flowmeter performance under asymmetric air flow profile[J]. Ultrasonics, 2021, 115: 106479. doi: 10.1016/j.ultras.2021.106479 [41] Sakhavi N, Nouri N M. Performance of novel multipath ultrasonic phased array flowmeter using gaussian quadrature integration[J]. Applied Acoustics, 2022, 199: 109004. doi: 10.1016/j.apacoust.2022.109004 [42] Chen D S, Cao H B, Cui B L. Study on flow field and measurement characteristics of a small-bore ultrasonic gas flow meter[J]Measurement and Control, 2021, 54(5-6): 554-564. [43] 温钊. 基于时差法的油流速超声测量方法研究[D]. 北京: 华北电力大学, 2021. [44] 姚爽, 宿彬, 杨宗良, 等. 上游弯管对超声波流量计精度影响及整流设计[J]. 仪器仪表学报, 2022, 43(5): 102-109. [45] 邵欣, 王涛, 高芦宝, 等. 基于CFD的超声波气体流量计过渡区内流场检测优化研究[J]. 中国测试, 2021, 47(10): 114-122. [46] Peng S B, Zhang Y, Zhao W W, et al. Analysis of the influence of rectifier blockage on the metering performance during shale gas extraction[J]. Energy & Fuels, 2021, 35(3): 2134-2143. [47] 贾秋红, 桂生, 王坤, 等. 交叉分段差分进化支持向量回归的气体超声流量计测量方法[J/OL]. [2024-03-22]. http://kns.cnki.net/kcms/detail/11.2121.O4.20230410.1134.002.html. [48] Xu Z J, Li M H, Han Y Q, et al. Robust flow estimation algorithm of multichannel ultrasonic flowmeter based on random sampling least squares[J]. Sensors, 2022, 22(19): 7660. doi: 10.3390/s22197660 [49] 樊玉光, 王引, 高琳, 等. 日照辐射对天然气超声波流量计流场修正系数的影响[J]. 计量科学与技术, 2023, 67(3): 56-64,34. [50] Lee S H, Choi H J, Choi H M, et al. Performance tests of flowmeters for fuel consumption measurements in fishing vessels[J]. Flow Measurement and Instrumentation, 2021, 80: 101959. doi: 10.1016/j.flowmeasinst.2021.101959 [51] 顾闽, 孙丽娜, 陈建楠, 等. 超声波流量计于计量设施在线校准的应用[J]. 江苏水利, 2022(5): 60-62,66. -

作者投稿

作者投稿 专家审稿

专家审稿 编辑办公

编辑办公

下载:

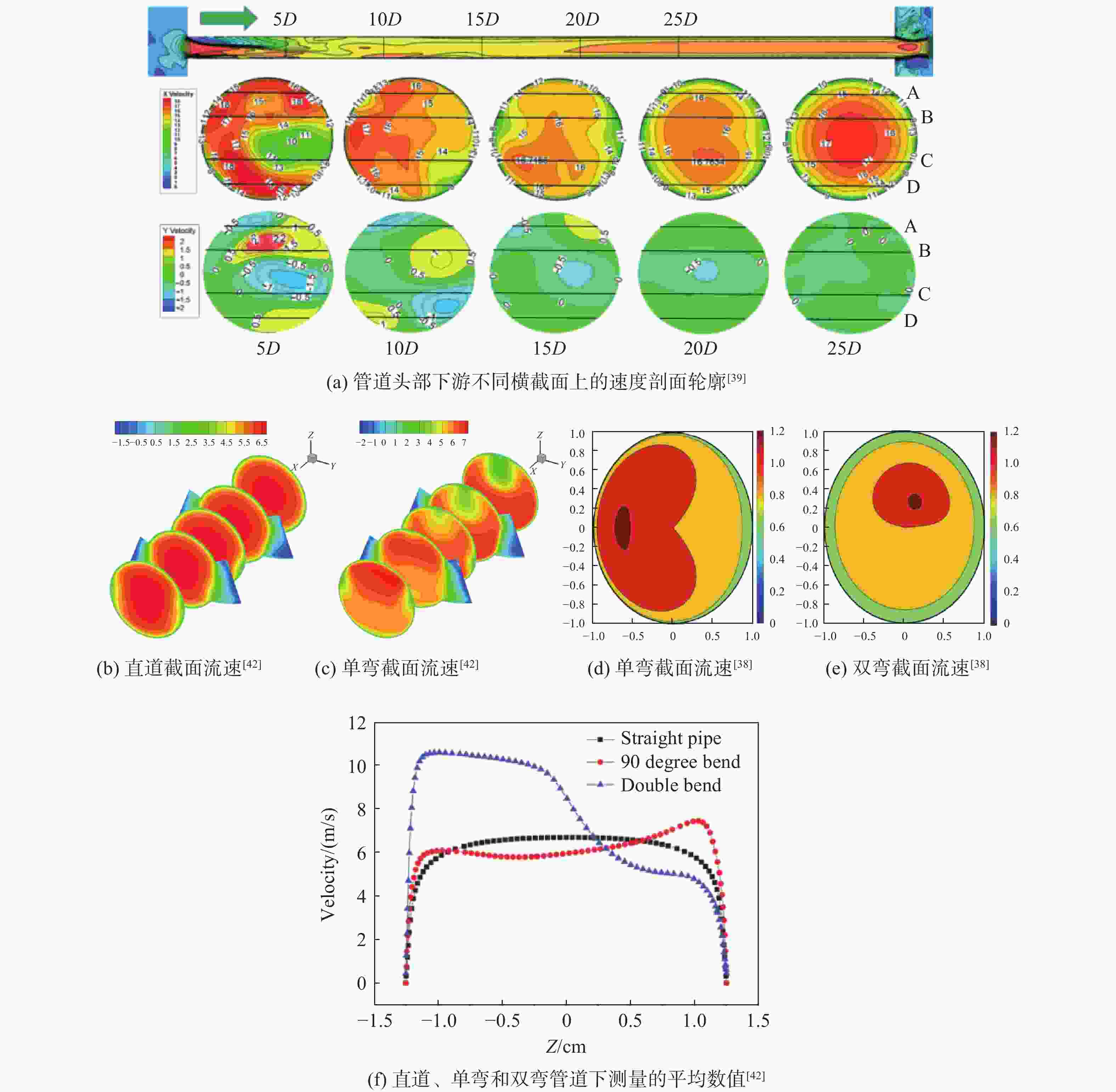

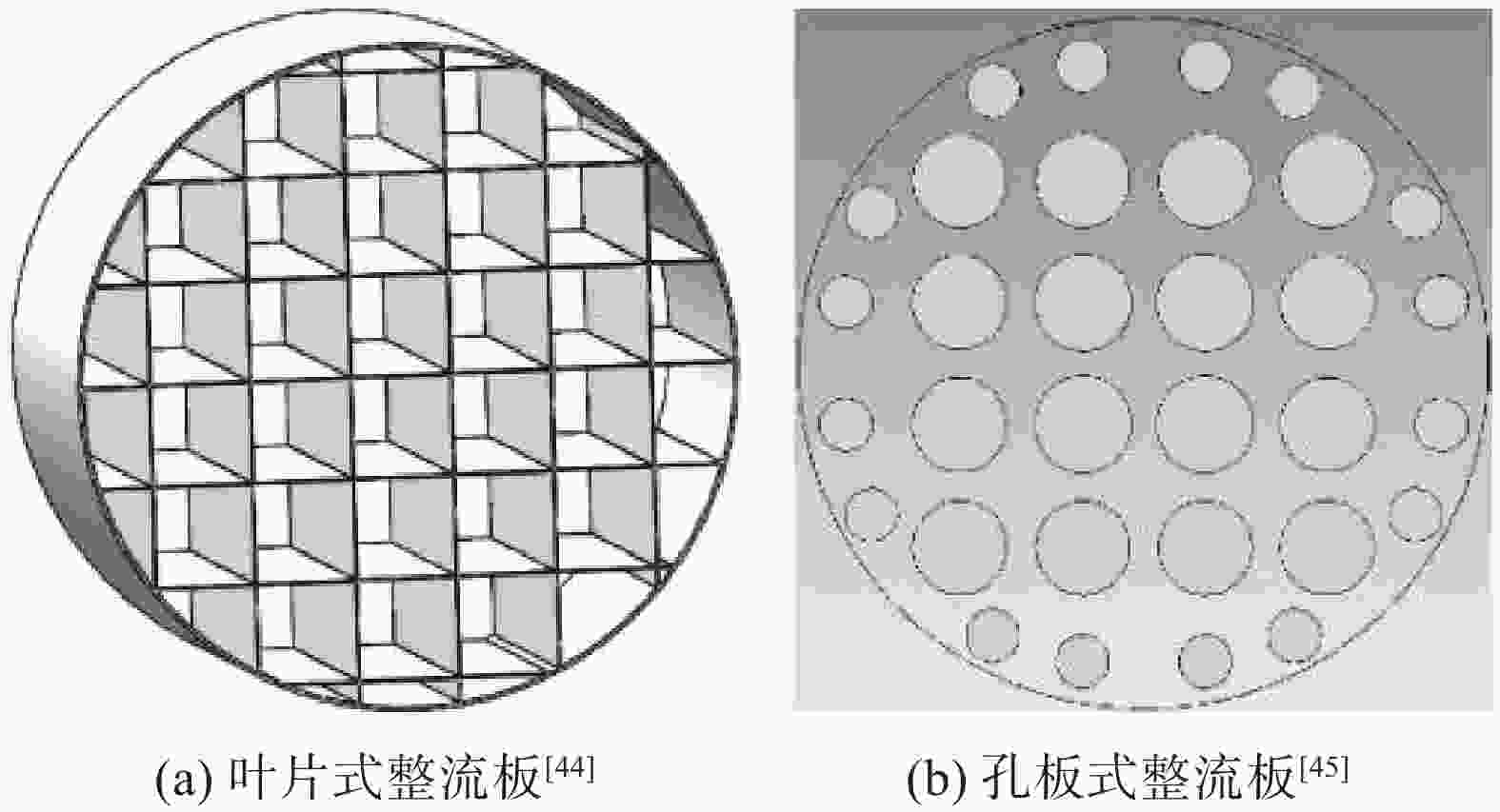

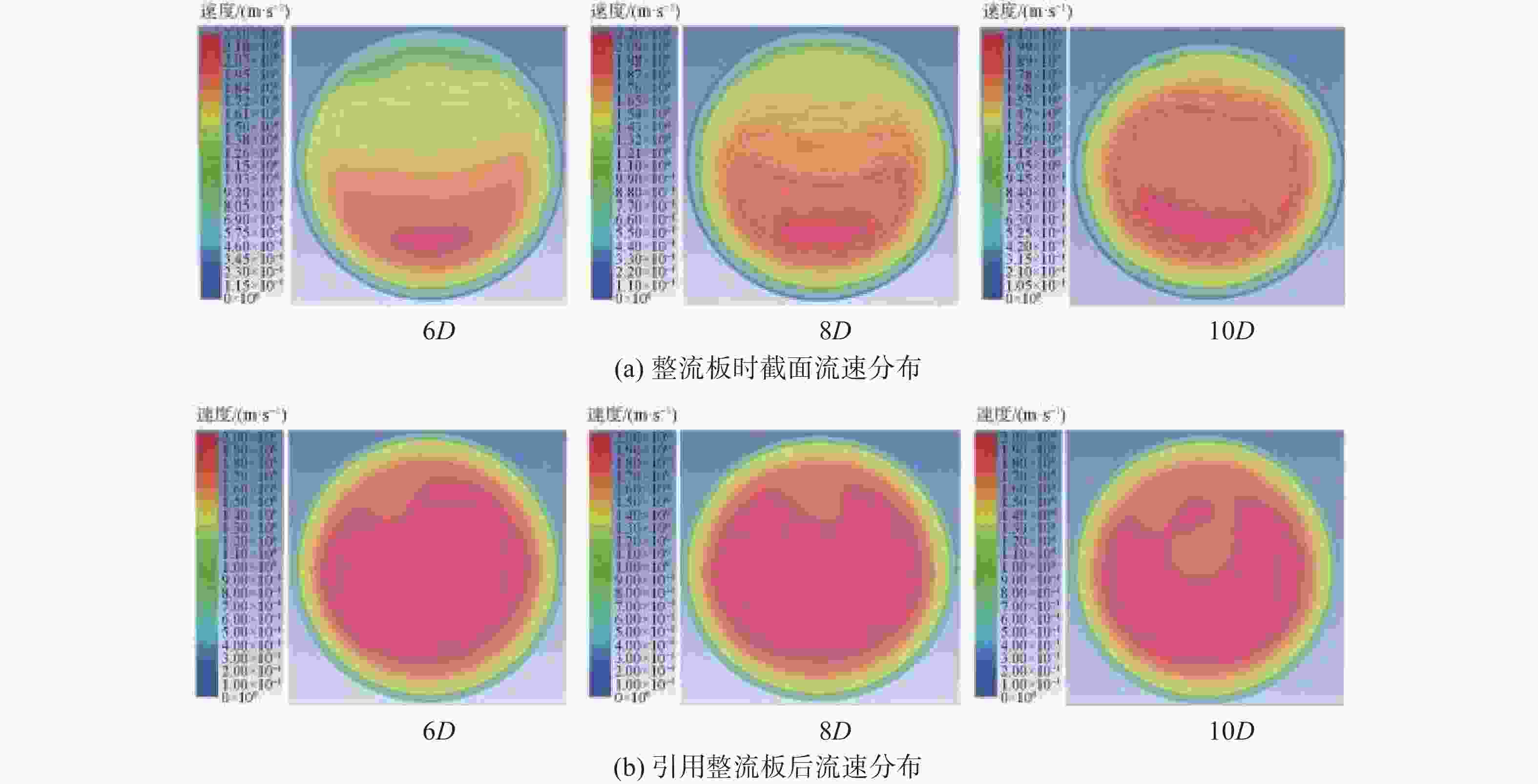

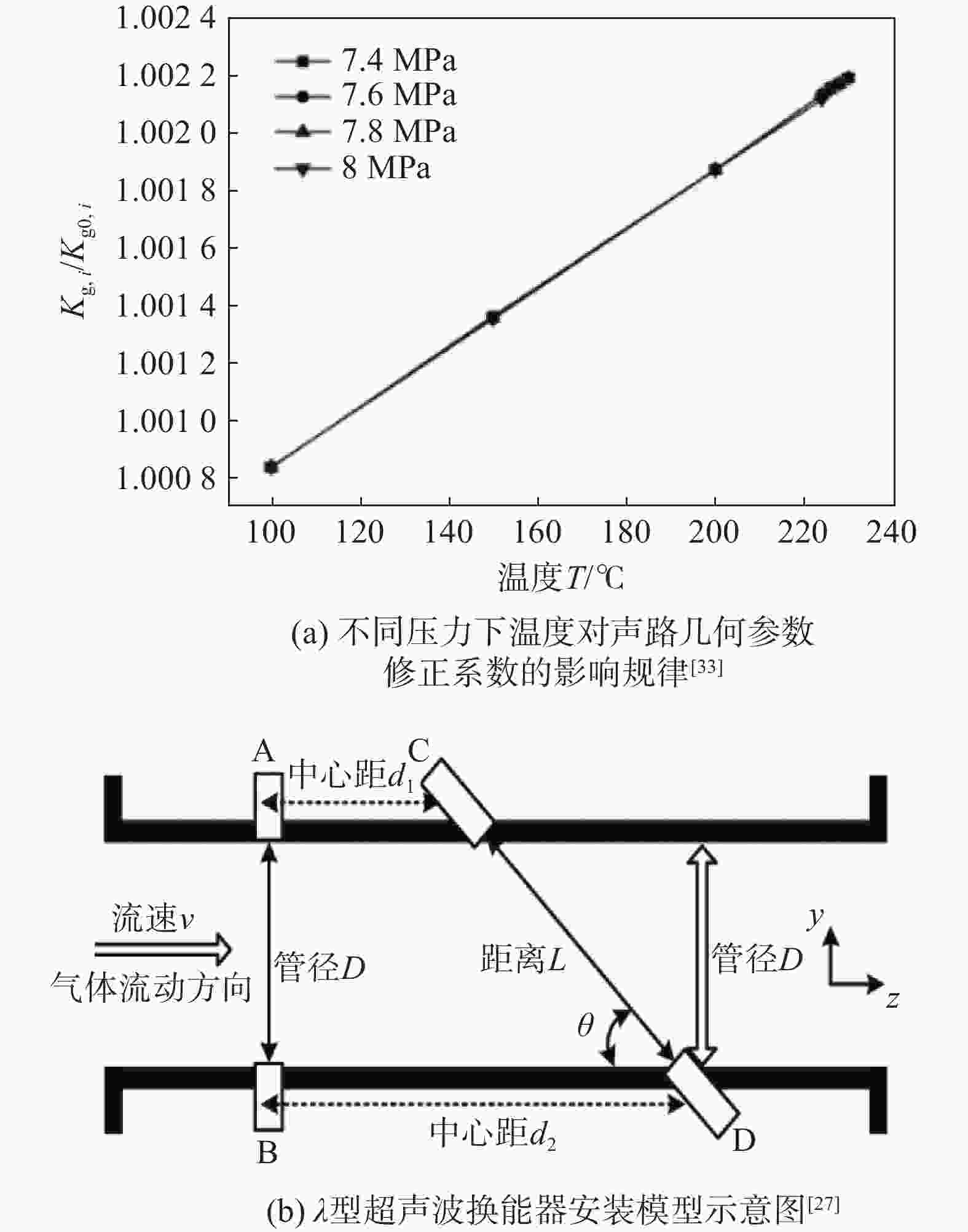

下载: