Advances and Applications in High-Precision Surface Coordinate Measurement Methods

-

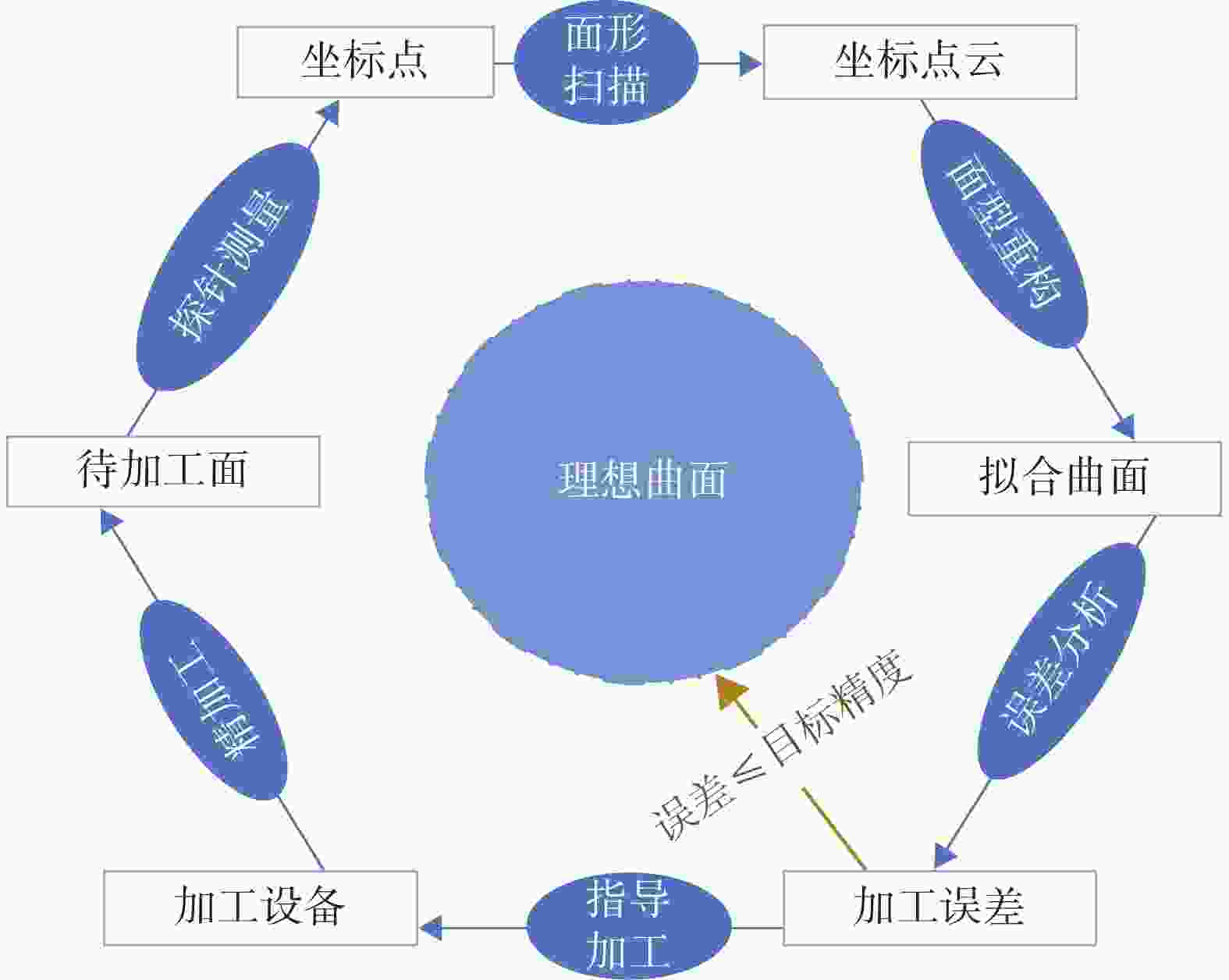

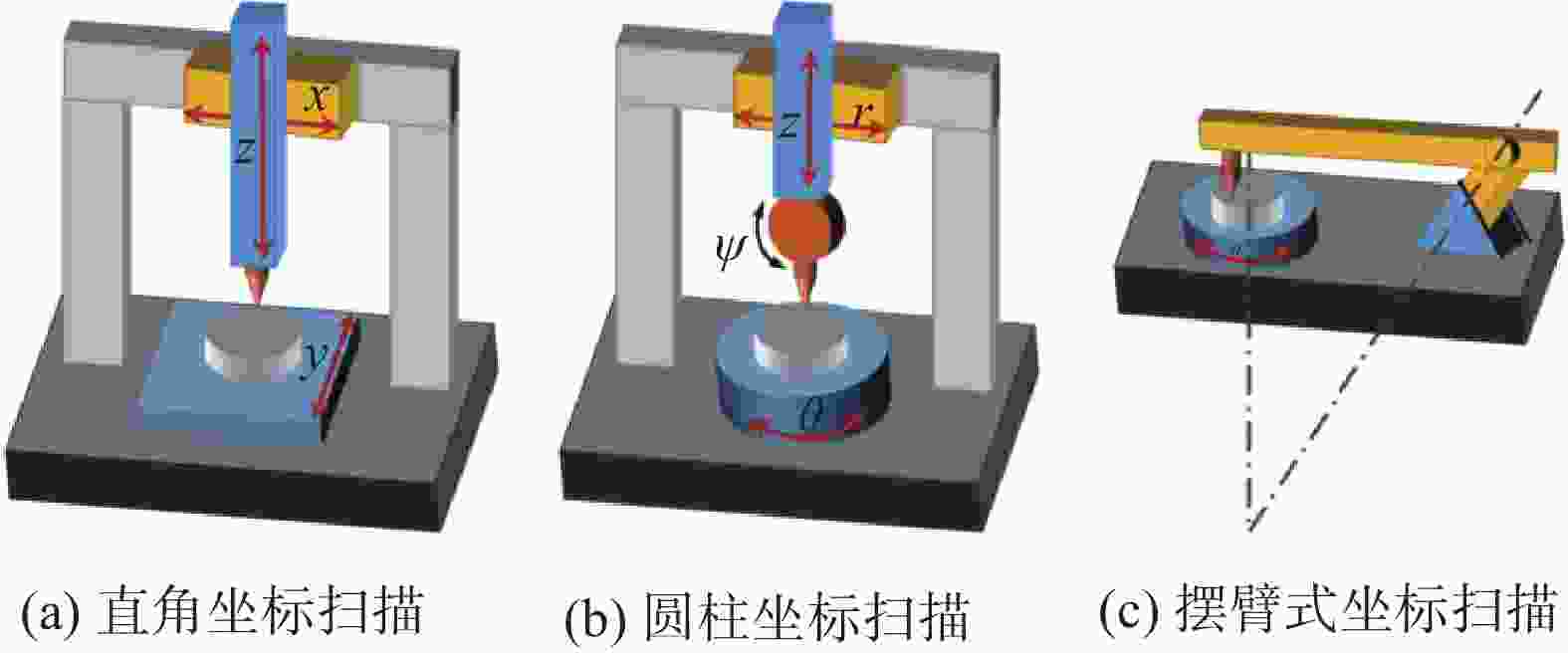

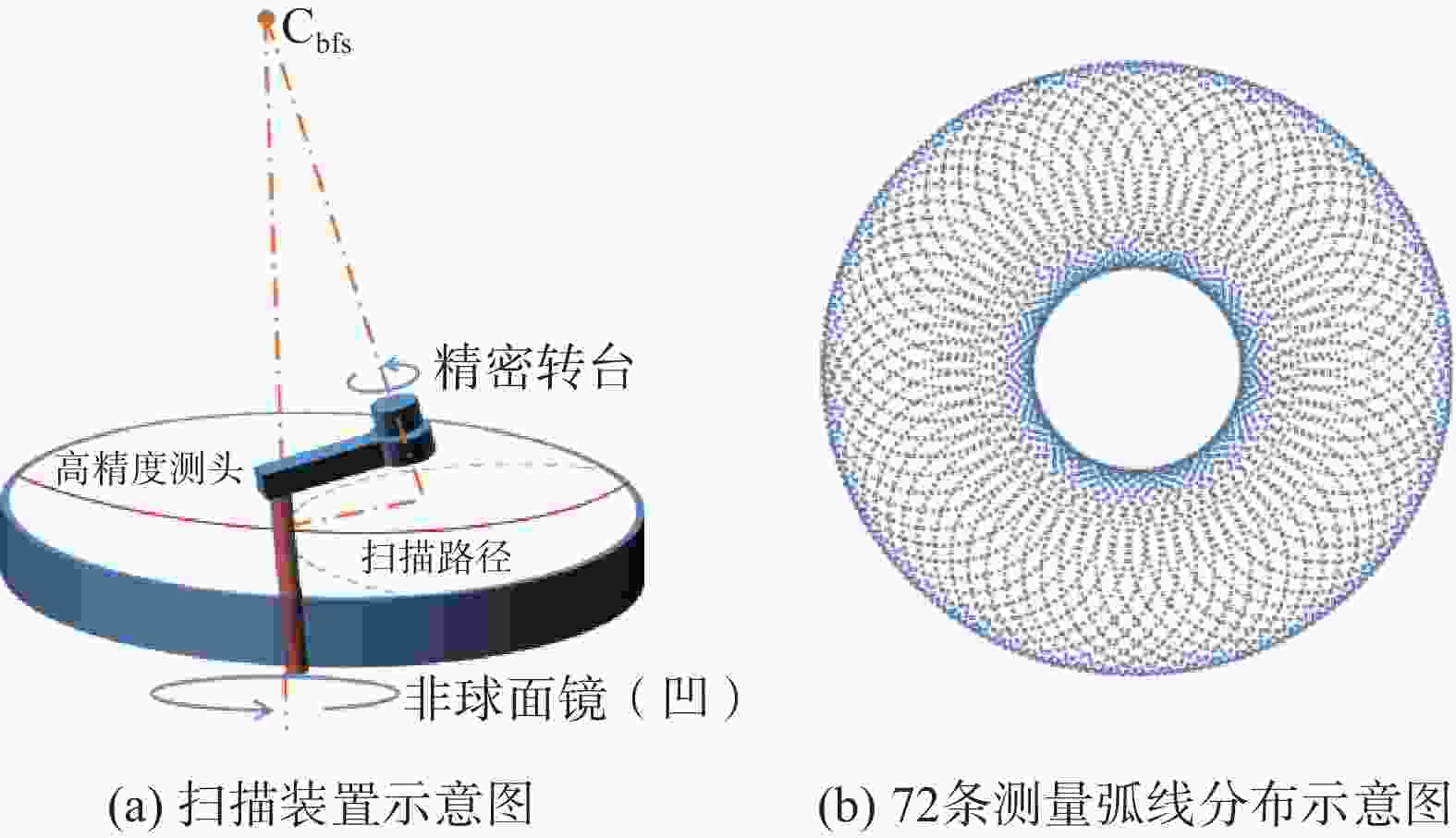

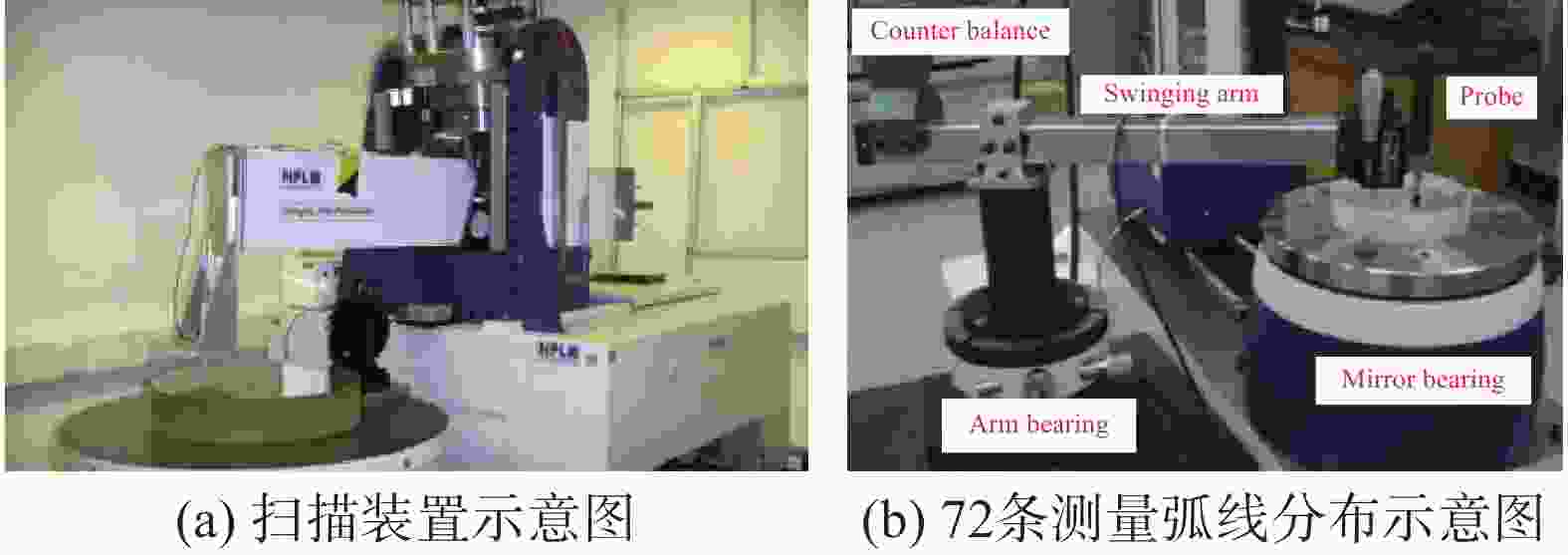

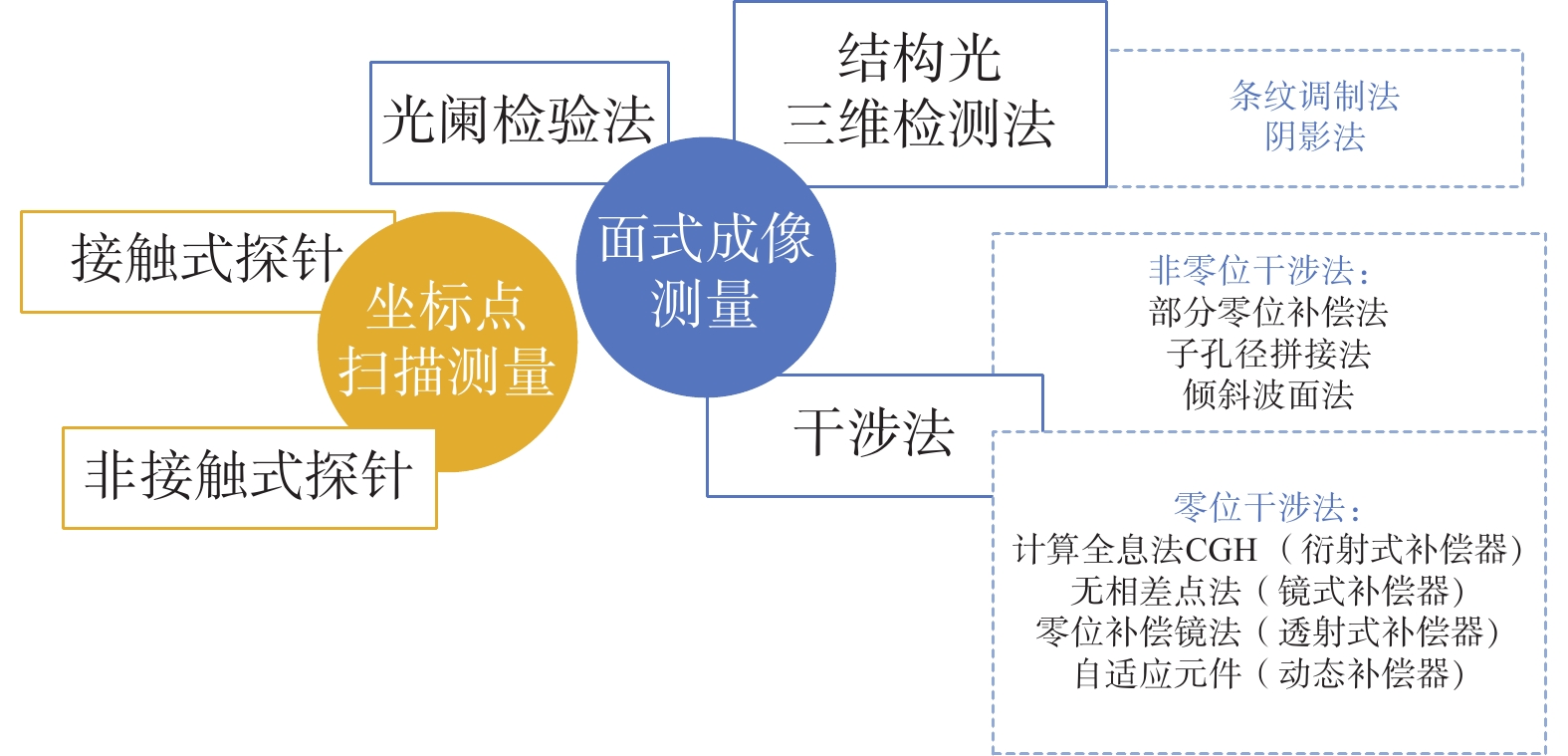

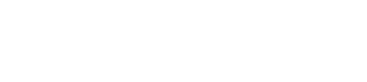

摘要: 随着光学元件加工技术的不断提升,复杂曲面光学元件在航空、航天、极紫外光刻等领域逐渐展露出其卓越的应用价值。全面回顾了高精度面形测量方法在复杂曲面光学元件研究中的进展和应用。重点关注通用性较高的坐标点扫描测量方法,详细介绍其发展历程和研究进展,分析讨论了不同方法的适用范围和优缺点。综合国内外先进的测量技术与方法,提出了一种基于微型干涉测头的标准非球面面形测量装置,以期解决面形测量仪器的量值统一和溯源问题,为复杂曲面的高精度测量提供了新的可行性方案。最后简要概括了复杂曲面测量领域的重点研究方向和可能的发展趋势。Abstract: The rapid evolution in optical component processing technology has notably enhanced the application of complex surface optical elements in various domains, including aviation, aerospace, and extreme ultraviolet lithography. These advancements have brought revolutionary changes in optical design and present substantial challenges in processing technology due to precision requirements. Consequently, there is an increasing demand for inspecting profiles and establishing standards in the metrology of freeform optical surfaces. This paper provides an extensive review of the progress and applications of high-precision surface form measurement methods for complex surface optical components. It primarily focuses on the widely applicable coordinate point scanning measurement methods, elaborating on their historical development, research progress, applicability, advantages, and limitations. The paper synthesizes advanced domestic and international measurement techniques and proposes a novel standard aspherical surface measurement device, integrating a miniature interferometric probe. This innovation aims to address the challenges of uniformity and traceability in surface measurement instruments, providing a practical approach for high-precision measurements of complex surfaces. Additionally, the paper delineates the key research directions and potential development trends in the field of complex surface measurement, emphasizing the significance of further advancements in this area.

-

表 1 Nano-CMM规格参数设计

Table 1. Nano-CMM parameter design

CMM Nano-CMM 设备尺寸 (2000 mm)3 (200 mm)3 设备质量 1000 kg 10 kg 测量尺寸 (1 m)3 (10 mm)3 分辨力 1 μm 10 nm 测量精度 5 μm 50 nm 测头尺寸 5 mm 50 μm 测头压力 10−1N 10−3N 表 2 Isara 400测量不确定度

Table 2. Isara 400 measurement uncertainty

测量不确定度 (nm)( k=2) 1D 52 (X axis) 49 (Y axis) 57 (Z axis) 2D 72(X/Z axis) 70(Y/Z axis) 71 (X/Yaxis) 3D 109 -

[1] 李池娟, 孙昌锋, 席喆, 等. 非球面光学零件的应用[J]. 激光与红外, 2013, 43(3): 4. [2] 梁子健, 杨甬英, 赵宏洋, 等. 非球面光学元件面型检测技术研究进展与最新应用[J]. 中国光学, 2022, 15(2): 26. [3] 黄岳田. 单点金刚石车削复杂曲面技术研究[D]. 成都: 中国科学院大学(中国科学院光电技术研究所), 2019. [4] 杨辉. 光学复杂曲面的先进制造技术[C]. 军工精密与特种加工技术交流会, 2007: 67-76. [5] 赖涛. 光学复杂曲面轮廓的坐标测量技术[D]. 长沙: 国防科技大学, 2021. [6] TSAY D M, CHENH C, HER M J. A study on five-flank machining of centrifugalcompressor impellers[J]. Journal of engineering for gas turbines and power, 2002, 124(1): 177-181. doi: 10.1115/1.1413768 [7] 周志雄, 周秦源, 任莹晖. 复杂曲面加工技术的研究现状与发展趋势[J]. 机械工程学报, 2010, 46(17): 105-113. [8] 程德文, 陈海龙, 王涌天, 等. 复杂光学曲面数理描述和设计方法研究[J]. 光学学报, 2023, 43(8): 137-163. [9] 张文浩. 非接触坐标测量技术及典型光学元件测量实验研究[D]. 杭州: 浙江大学, 2019. [10] 中国工程院全球工程前沿项目组. 全球工程前沿[M]. 北京: 高等教育出版社, 2020. [11] 朱日宏, 孙越, 沈华. 光学自由曲面面形检测方法进展与展望[J]. 光学学报, 2021, 41(1): 161-178. [12] 张金平, 张学军, 张忠玉, 等. Shack-Hartmann波前传感器检测大口径圆对称非球面反射镜[J]. 光学精密工程, 2012, 20(3): 492-498. [13] GREVIENKAMP J E, GAPPINGER R O. Design of a nonnull interferometer for aspheric wave fronts[J]. Applied optics, 2004, 43(27): 5143-5151. doi: 10.1364/AO.43.005143 [14] 刘东, 严天亮, 王道档, 等. 条纹投影与相位偏折测量技术研究进展[J]. 红外与激光工程, 2017, 46(9): 193-202. [15] DENG X T, GAO N, ZHANG Z H. A calibration method for system parameters in direct phase measuring deflectometry[J]. Applied Sciences, 2019, 9(7): 1444. doi: 10.3390/app9071444 [16] 席庆奎, 朱日宏, 陈磊, 等. 计算全息用于非球面检测的方法[J]. 激光杂志, 2004, 25(6): 67-69. [17] XUE SH, CHEN SH Y, FAN ZH B, et al. Adaptive wavefront interferometry for unknown free-form surfaces[J]. Optics Express, 2018, 26(17): 21910-21928. doi: 10.1364/OE.26.021910 [18] 陈善勇, 卢劲丰, 薛帅. 波面干涉测量中的可变像差补偿技术[J]. 激光与光电子学进展, 2017, 54(4): 57-68. [19] 陈善勇, 薛帅, 熊玉朋, 等. 面向制造的光学面形超精密测量技术研究进展[J]. 激光与光电子学进展, 2023, 60(3): 177-190. [20] 田超. 非球面非零位环形子孔径拼接干涉检测技术与系统研究[D]. 杭州: 浙江大学, 2013. [21] 师途. 基于部分零位补偿透镜的非球面通用化检测技术研究[D]. 杭州: 浙江大学, 2017. [22] 梁子健. 基于计算全息的非球面零位共路干涉检测技术研究[D]. 杭州: 浙江大学, 2021. [23] 张金平. 夏克—哈特曼波前传感器检测大口径非球面应用研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2012. [24] SLADEK J A. Coordinate Metrology: Accuracy of Systems and Measurements[M]. Berlin : Springer, 2016. [25] 陈雪芳. 逆行工程与快速成型技术应用[M]. 北京: 机械工业出版社, 2009. [26] 佚名. 蔡司工业测量一站式的测量解决方案供应商[J]. 模具制造, 2014(5): 14-15. [27] 谭久彬. 超精密测量技术与仪器工程研究中的几个热点问题[J]. 中国机械工程, 2000(3): 25-29,4. [28] 谭久彬. 超精密测量技术与仪器是高端制造发展的前提与基础[J]. 激光与光电子学进展, 2023, 60(3): 11-12. [29] 罗霄. 采用平转动应力盘技术加工超大口径非球面的研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2011. [30] 殷龙海. 大中型SiC非球面反射镜确定性高效加工工艺的研究[D]. 长春: 中国科学院研究生院(长春光学精密机械与物理研究所), 2015. [31] 杜航. 空间大口径非球面SiC反射镜高效高精度加工关键技术研究[D]. 长沙: 国防科技大学, 2018. [32] 陈帅. 共面导轨三维轮廓测量仪关键技术研究[D]. 长沙: 国防科技大学, 2017. [33] ANDERSON D S, PARKS R E, SHAO T. A versatile profilometer for aspheric optics[J]. Technical Digest on Optical Fabrication and Testing, 1990, 11: 119-122. [34] ANDERSON D S, BURGE J H. Swing-arm profilometry of aspherics[C]. American: SPIE, 1995. [35] SU P , OH C J , PARKS R E , et al. Swing arm optical CMM for aspherics[J]. Proceedings of SPIE - The International Society for Optical Engineering, 2009, 7426: 74260J-74260J-8. [36] SU P , OH C J , ZHAO C , et al. Optical testing for meter size aspheric optics[C]. Instrumentation, Metrology, and Standards for Nanomanufacturing, Optics, and Semiconductors VI, 2012, 8466: 84660S. [37] SU P, PARKS R E, WANG Y H, et al. Swing-arm optical coordinate measuring machine: modal estimation of systematic errors from dual probe shear measurements[J]. Optical Engineering, 2012, 51(4): 043604. doi: 10.1117/1.OE.51.4.043604 [38] WANG Y H, SU P, Parks R E, et al. Swing-arm optical coordinate measuring machine: high precision measurement of ground aspheric surfaces using a laser triangulation probe[J]. Optical Engineering, 2012, 51(7): 073603. doi: 10.1117/1.OE.51.7.073603 [39] ANDREW L, OLDFIELD S. Accurate arm profilometry - traceable metrology for large mirrors [C]. Proceedings of Simposio de Metrología, 2006. [40] EFSTATHIOU A. Design considerations for a hybrid swing-arm profilometer to measure large aspheric optics[D]. London: University of London, 2007. [41] Lewis A. Uncertainty budget for the NPL-UCL swing arm profilometer operating in comparator mode[M]. London: HMSO and Queen’s printer, 2008. [42] CALLENDER M J, EFSTATHIOU A, KING C W, et al. A Swing arm profilometer for large telescope mirror element metrology [C]. International Society for Optics and Photonics, 2006. [43] JING H W, KING C, WALKER D. Simulation and validation of a prototype swing arm prof-ilometer for measuring extremely large telescope mirror-segments[J]. Optics Express, 2010, 18(3): 2036-2048. doi: 10.1364/OE.18.002036 [44] JING H W, LIN Z H, MA L F, et al. Development and experimental validation of a versatile prototype Swing Arm Profilometer for measuring optical surface[J]. Journal of European Optical Society-Rapid Publications, 2011, 6: 11052. doi: 10.2971/jeos.2011.11052 [45] Wei Z W, JING H W, KUANG L, et al. Error separation technique for measuring aspheric surface based on dual probes [C]. International Symposium on Photoelectronic Detection and Imaging 2013: Laser Sensing and Imaging and Applications, 2013. [46] 魏中伟. 摆臂式轮廓仪工件转台误差分离技术研究[D]. 成都: 中国科学院研究生院(光电技术研究所), 2014. [47] CHEN L, JING H W, WEI Z W, et al. Research on the measurement technology of effective arm length of swing arm profilometer[C]. 7th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Large Mirrors and Telescopes, 2014. [48] 陈林. 摆臂式轮廓仪测头空间位置检测技术研究[D]. 成都: 中国科学院研究生院(光电技术研究所), 2015. [49] GAO M X, JING H W, FAN T Q, et al. Calibrating the axes of the swing arm profilometer by the four-based laser trackers [C]. 2015 International Conference on Optical Instruments and Technology: Optoelectronic Measurement Technology and Systems, 2015. [50] 高明星. 摆臂式轮廓仪旋转轴空间状态标定技术研究[D]. 成都: 中国科学院研究生院(光电技术研究所), 2016. [51] 张鑫. 提高大口径光学反射镜加工收敛效率的关键技术研究[D]. 长春: 长春光学精密机械与物理研究所, 2016. [52] 李龙响. 大口径非球面磁流变加工的关键技术研究[D]. 长春: 长春光学精密机械与物理研究所, 2016. [53] 熊玲, 罗霄, 刘振宇, 等. 2 m量级SiC非球面反射镜的摆臂轮廓检测[J]. 光学学报, 2015, 35(12): 166-172. [54] 熊玲. 大口径复杂光学曲面的摆臂式轮廓测量技术研究[D]. 长春: 中国科学院长春光学精密机械与物理研究所, 2017. [55] OGDEN H. Applications of numerical measuring systems-In Numerical Control User’s Handbook[M]. New York: McGraw Hill Publishing Co. , LTD, 1970: 377. [56] HOCKEN R J . Coordinate Measuring Machines and Systems(Second Edition)[M]. Netherlands: Crc Press, 2017. [57] Fan K C , Fei Y T , Yu X F , et al. Development of a low-cost micro-CMM for 3D micro/nano measurements[J]. Measurement Science and Technology, 2006, 17(3): 524-532. [58] TAKAMASU K, HIRAKIi M , ENAMI K , et al. Development of Nano-CMM and Parallel-CMM—CMM in the 21th Century[J]. International Dimensional Metrology Workshop , 1999, 5: 10-13. [59] WERNER K. XENOS–the new standard[J]. Advanced Technologies in Mechanics, 2014, 1(1): 28-31 [60] SALAH H R A. State-of-the-Art of CMM-Coordinate Metrology in Automotive Industry[C]. SAE World Congress Experience, 2017. [61] SEGGELEN J K V, ROSIELLE P, SCHELLEKENS P H J, et al. An elastically guided machine axis with nanometer repeatability[J]. CIRP Annals - Manufacturing Technology, 2005, 54(1): 487-490. doi: 10.1016/S0007-8506(07)60151-6 [62] JANTZEN S, STEIN M, KNIEL K, et al. Microclamping principles from the perspective of micrometrology–A review[J]. Precision Engineering, 2017, 50: 538-550. doi: 10.1016/j.precisioneng.2017.07.008 [63] RUIJL T. Ultra-precision coordinate measuring machine: design, calibration and error compensation[D]. Netherlands: Technique University Eindhoven, 2001 [64] SPAAN H A M, DONKER R L, WIDDERSHOVEN I. Isara 400: development of an ultraprecision CMM for 3D measurement of large parts[C]. Proceedings of the ASPE spring topical conference, 2009. [65] SPAAN H A M, WIDDERSHOVEN I. Isara 400 ultra-precision CMM[C]. International Society for Optics and Photonics, 2011. [66] DONKER R L, WIDDERSHOVEN I, SPAAN H A M. Isara 400: Enabling ultra-precision coordinate metrology for large parts[C]. IBS Precision Engineering: International Symposium on Measurement and Quality Control, 2010. [67] WIDDERSHOVEN I, DONKER R L, SPAAN H A M. Realization and calibration of the" Isara 400" ultra-precision CMM[C]. International Society for Optics and Photonics, 2011. [68] DONKER R, WIDDERSHOVEN I, SPAAN H. Realization of Isara 400: a large measurement volume ultra-precision CMM[C]. Proceedings of the Asian Symposium for Precision Engineering and Nanotechnology, 2009. [69] DAI G L, NEUGEBAUER M, STEIN M, et al. Overview of 3D Micro-and Nanocoordinate Metrology at PTB[J]. Applied Sciences, 2016, 6(9): 257. doi: 10.3390/app6090257 [70] 贾立德. 光学非球面坐标测量关键技术研究[D]. 长沙: 国防科学技术大学, 2008. [71] LAI T, PENG X Q, TIE G P, et al. High accurate squareness measurement squareness method for ultra-precision machine based on error separation[J]. Precision Engineering-Journal of the International Societies for Precision Engineering and Nanotechnology, 2017, 49: 15-23. [72] HENSELMANS R . Non-contact measurement machine for freeform optics[D]. Netherlands: Technische Universiteit Eindhoven, 2009. [73] HENSELMANS R, CACACE L A, KRAMER G F Y, et al. The NANOMEFOS non-contact measurement machine for freeform optics[J]. Precision Engineering, 2011, 35(4): 607-624. doi: 10.1016/j.precisioneng.2011.04.004 [74] HENSELMANS R, CACACE L, KRAMER G, et al. Nanometer level freeform surface measurements with the NANOMEFOS non-contact measurement machine[C]. International Society for Optics and Photonics, 2009. [75] HENSELMANS R, GUBBELS G P H, VAN D C, et al. NANOMEFOS non-contact measurement machine for aspheric and freeform optics[C]. International Conference on Space Optics-ICSO 2010. International Society for Optics and Photonics, 2017. [76] HENSELMANS R, CACACE L, ROSIELLE N, et al. Design, realization and testing of the NANOMEFOS non-contact measurement machine for freeform optics[C]. Proceedings of ASPE Annual conference, 2008. [77] HENSELMANS R, CACACe L A, KRAMER G, et al. Development and performance demonstration of the NANOMEFOS non-contact measurement machine for freeform optics[M]. London: Euspen, 2009. [78] Dutch United Instruments. NMF Products specifications[EB/OL]. [2024-12-08].https://dutchunitedinstruments.com/form-metrology-products/#nmfproducts. [79] BERGER G , PETTER J . Non-contact metrology of aspheric surfaces based on MWLI tech-nology[C]. Optifab. International Society for Optics and Photonics, 2013. [80] JÜRGEN P, BERGER G. Non-contact profiling for high precision fast asphere topology measurement[C]. Spie Optical Metrology, 2013. [81] Taylor Hobson. Non-contact 3D optical profilers: LUPHOScan 850 HD[EB/OL]. [2024-12-08].https://www.taylor-hobson.com/products/non-contact-3d-optical-profilers/luphos/luphoscan-850-hd. [82] 张博, 严利平, 刁晓飞. 波片阵列对准误差对激光干涉非线性误差的影响[J]. 中国激光, 2022, 49(9): 9. [83] 范芯蕊, 刁晓飞, 吴剑威, 等. 高精度轴对称非球面反射镜轮廓测量方法(特邀)[J]. 红外与激光工程, 2022(9): 051. -

作者投稿

作者投稿 专家审稿

专家审稿 编辑办公

编辑办公

下载:

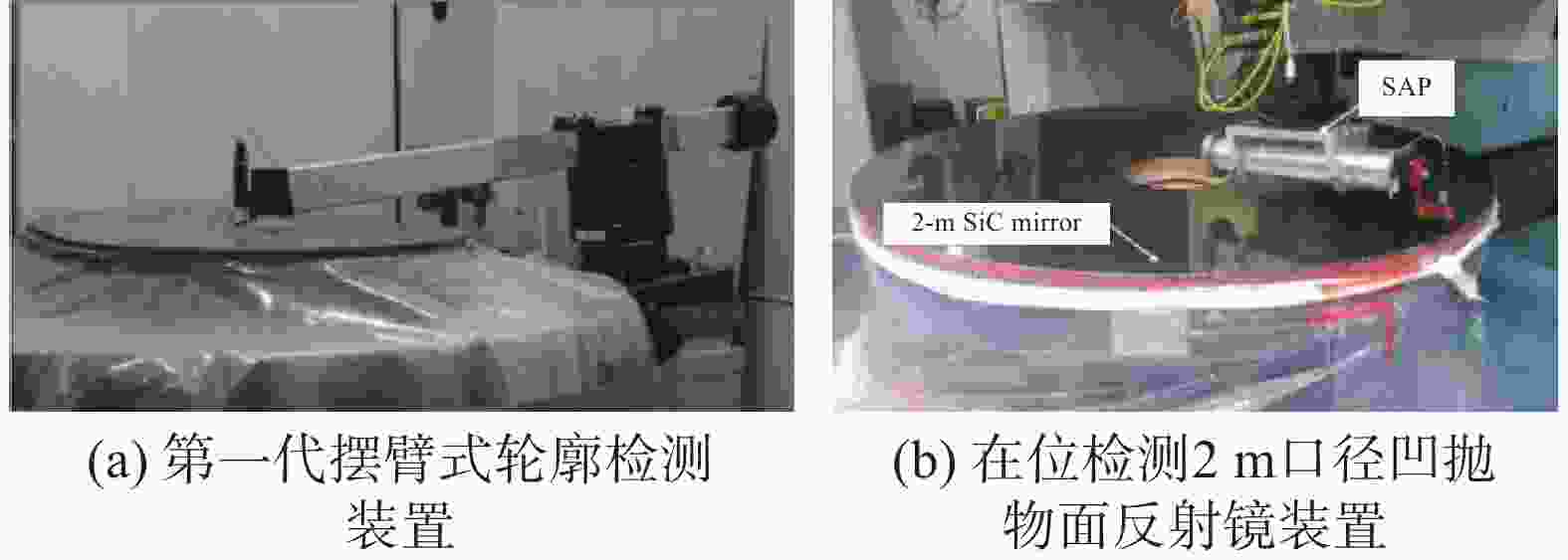

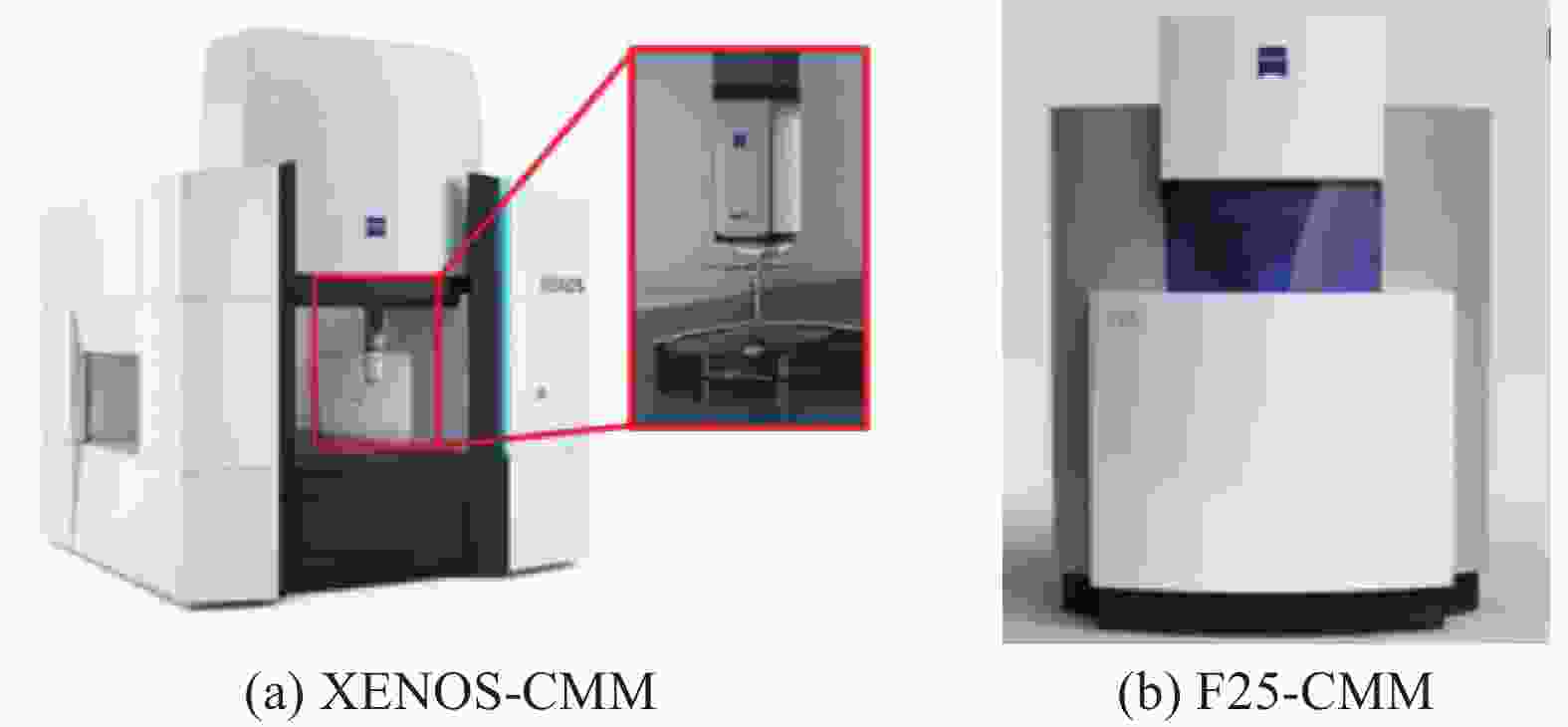

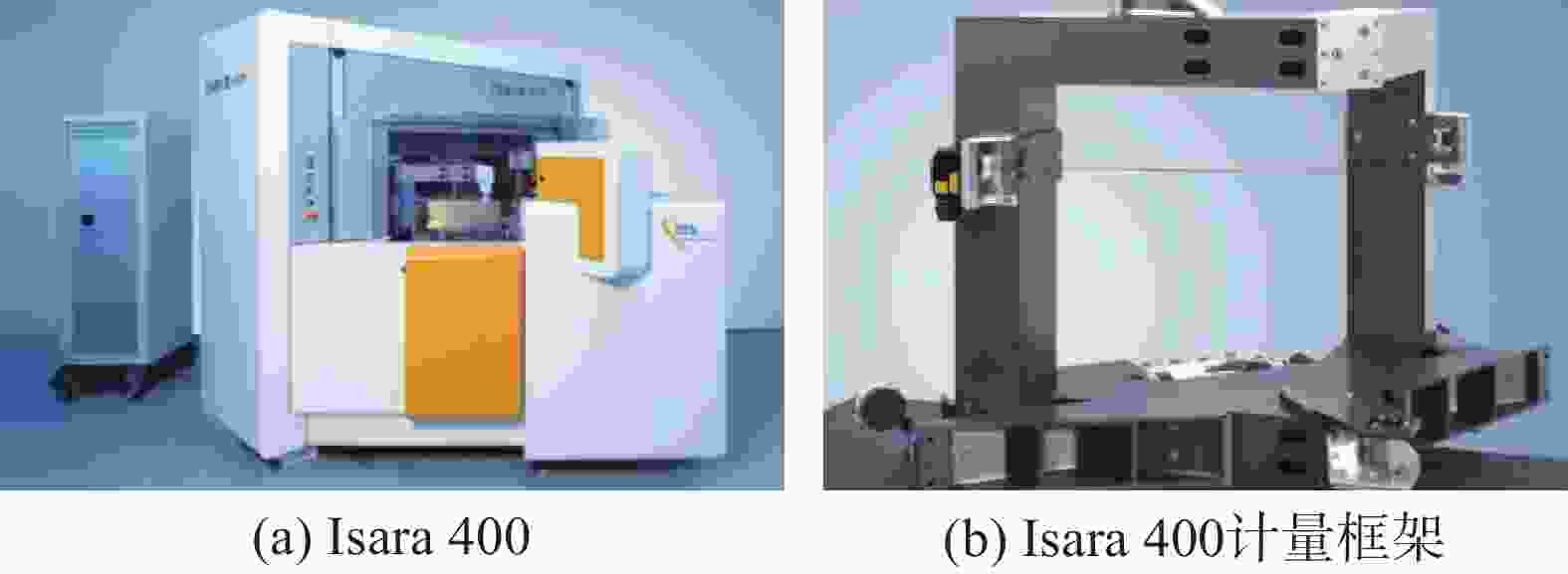

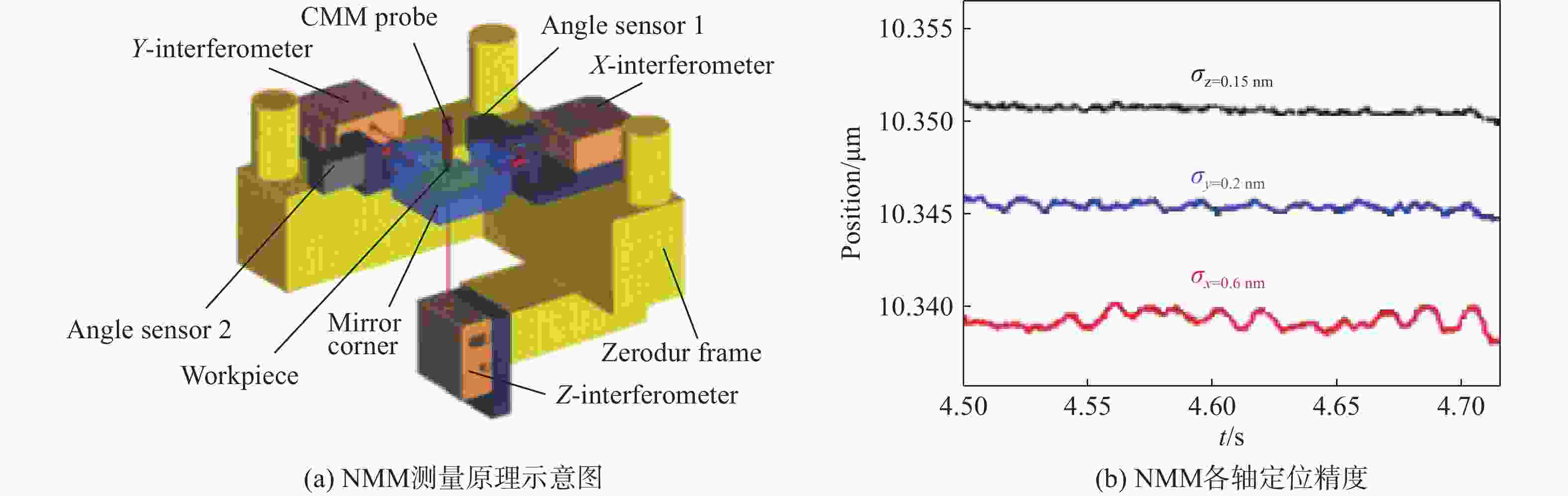

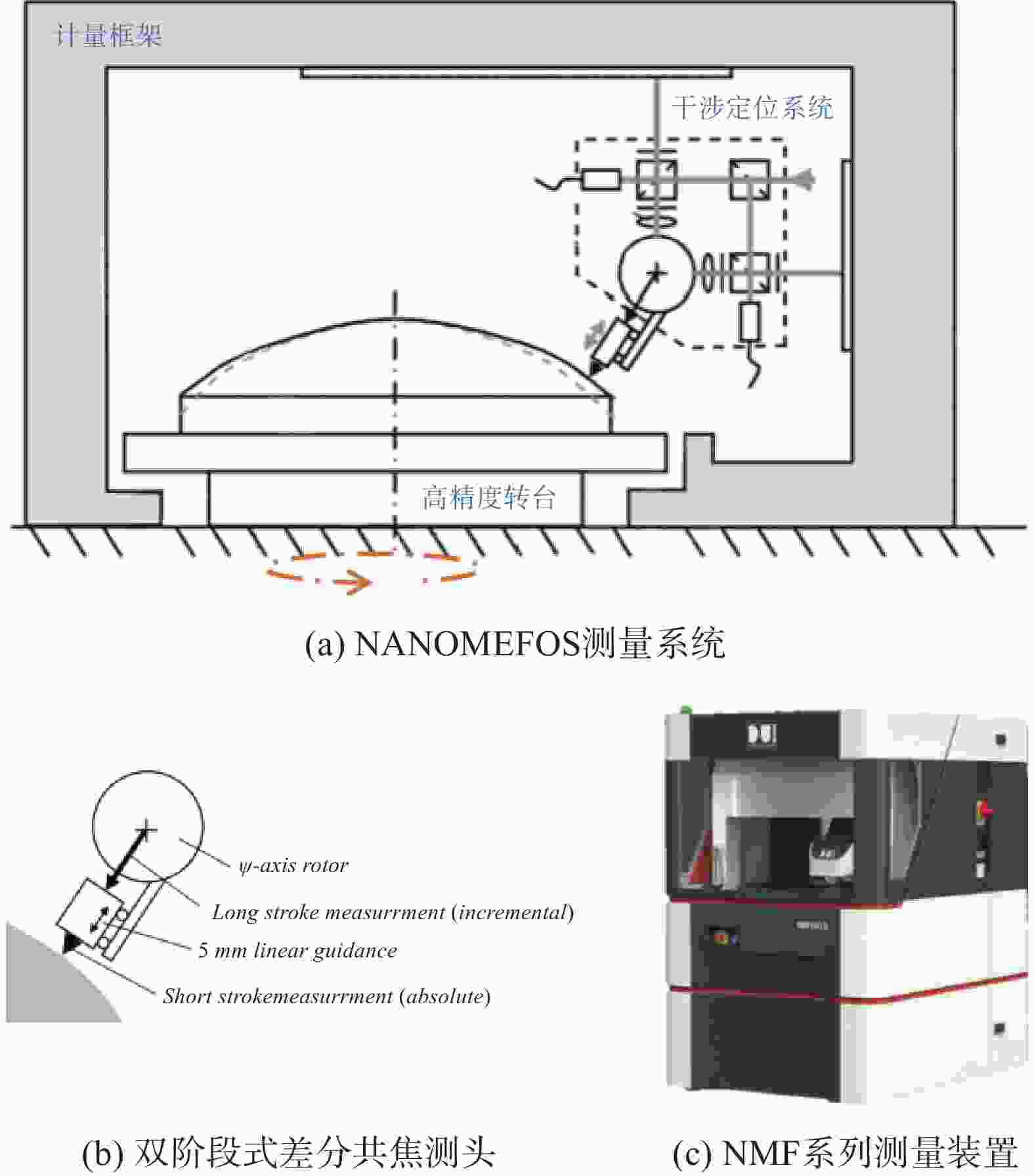

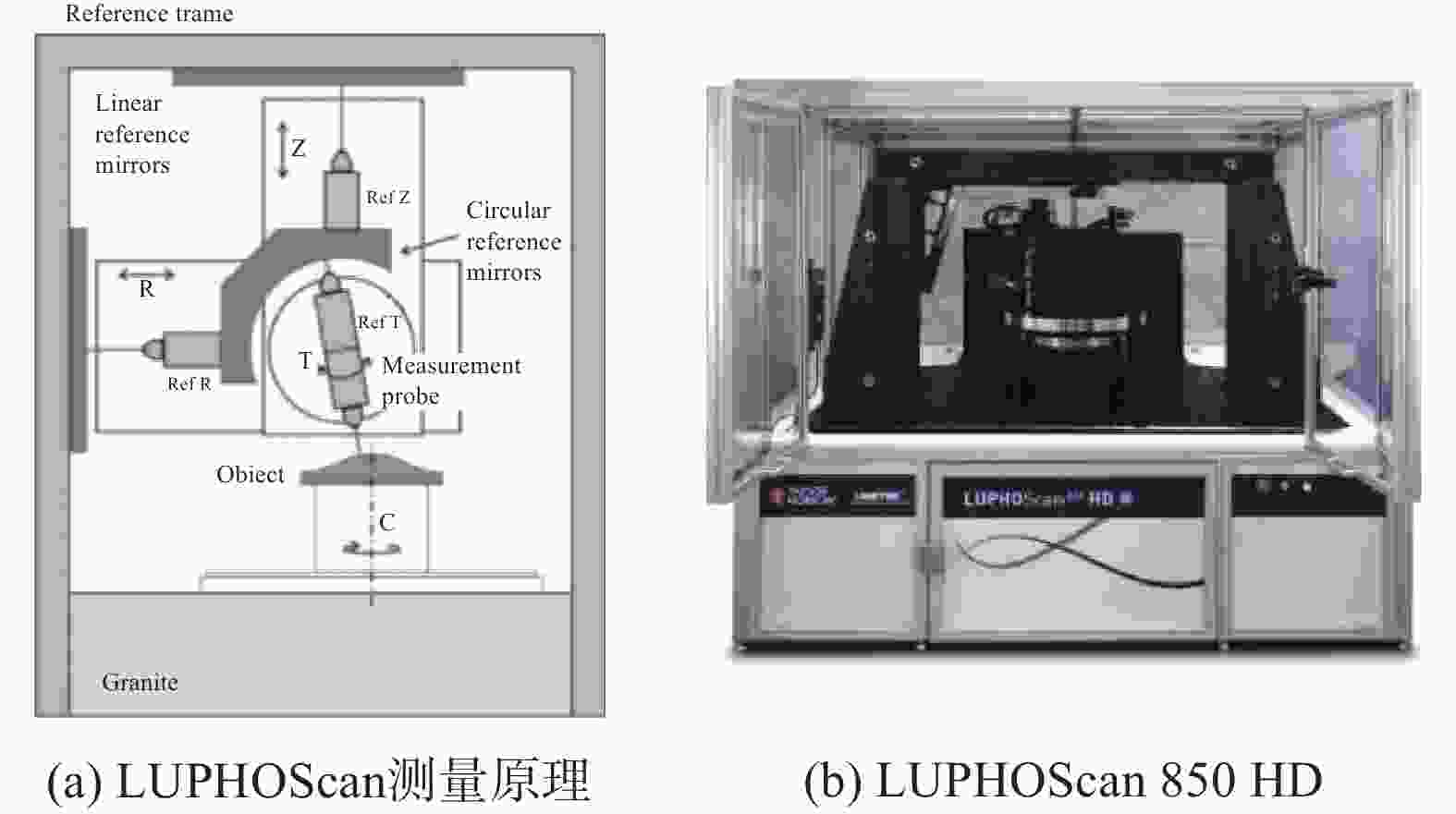

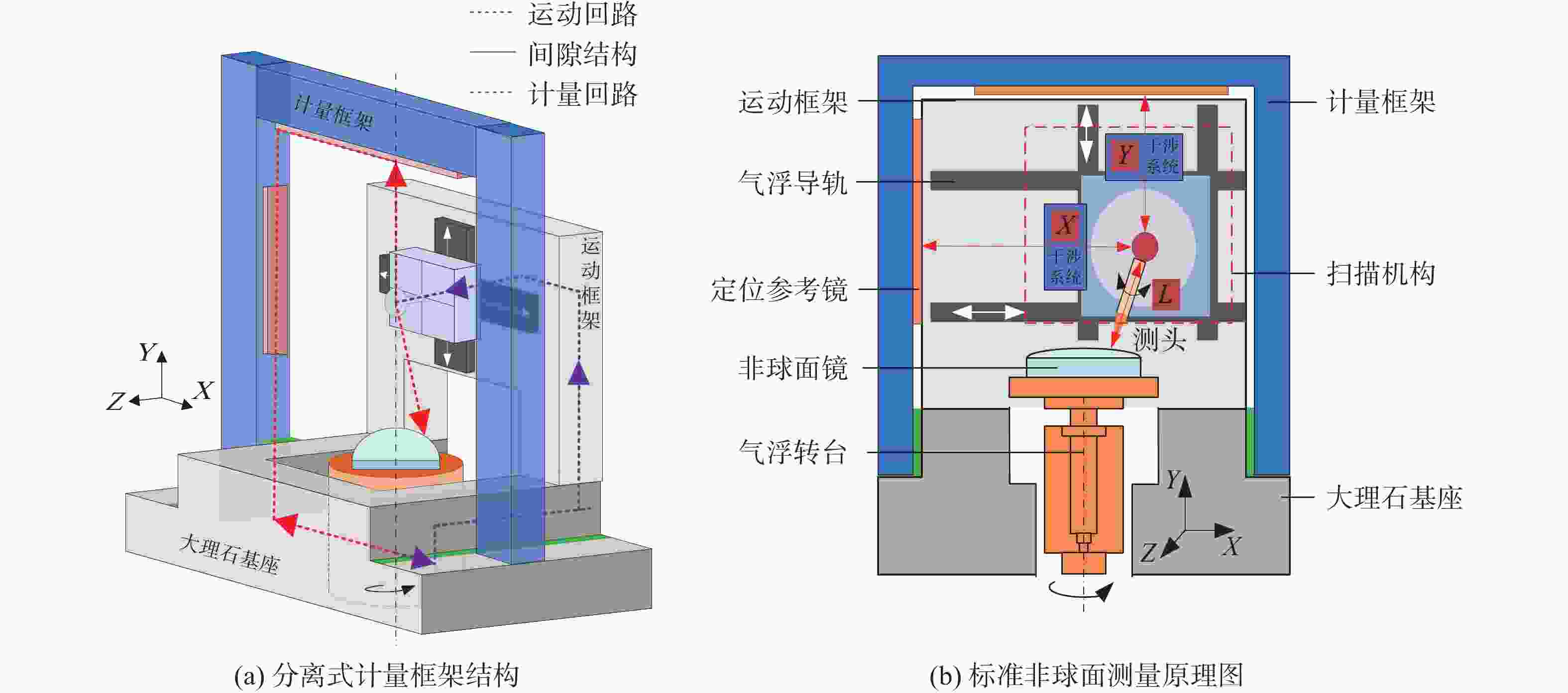

下载: